TRAIN SCS

Ultraviolet C irradiation for air sterilization in trains

Alteria Automation, Bytek, Alter Technology and secpho are collaborating in the TRAIN SCS project to develop an innovative air conditioning system that will improve air quality in trains, a major source of respiratory disease transmission.

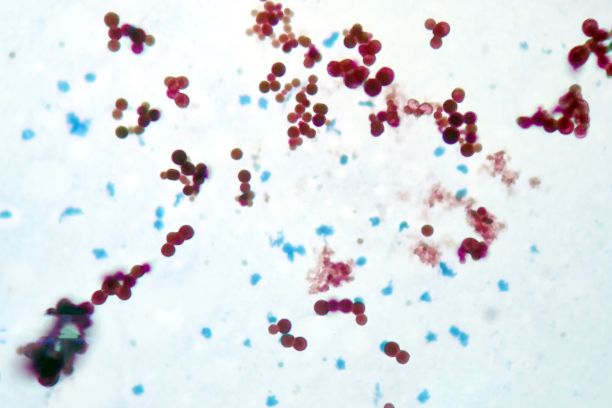

This project develops a new product that allows the sterilization of viruses and bacteria, as well as the monitoring of air quality for passenger vehicles and railroads (Metro, light rail, urban streetcars, commuter trains, AVE, ALVIA).

The initiative has received funding from the Ministry of Industry, Trade and Tourism corresponding to Next Generation EU funds, canalised through the support programme for Innovative Business Groups, whose objective is to digitalise industry.

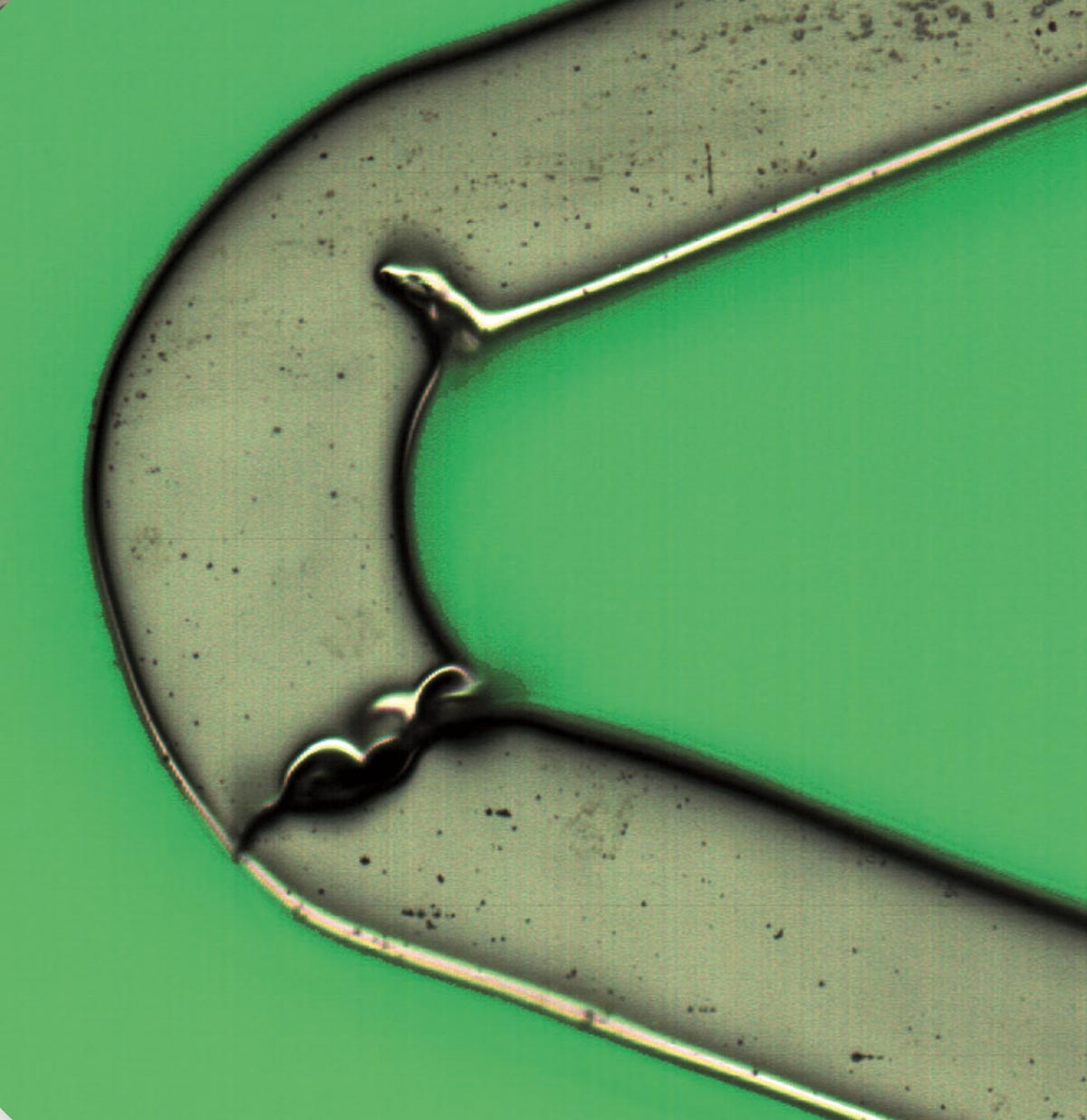

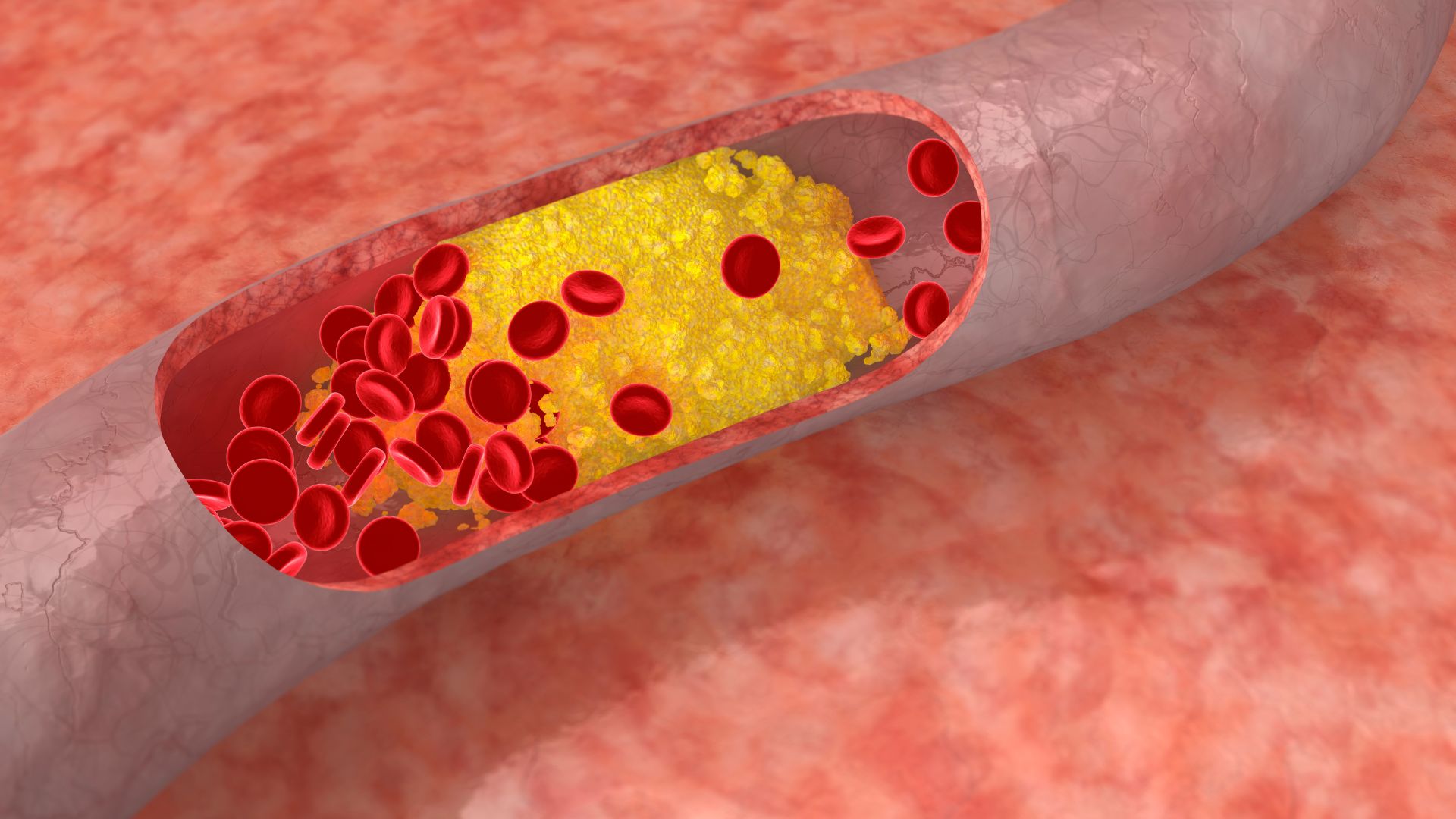

The railway air conditioning systems currently used were not designed to deal with the current problems of respiratory disease transmission: the air is conditioned by passing it over and over again through the air conditioning unit, without exchanging air with the outside air.

Commuter (urban) and inter-city public transport has an undeniably growing importance in the social structure of today’s Europe, since, among other things, pollution in cities is intended to be reduced by increasing the use of this type of transport, as well as by limiting the use of private vehicles in the city center. In view of the scarcity of energy resources due to recent events (SARS2 Covid19 pandemic, war in Ukraine, inflation, rising energy prices…), the use of public transport in cities has become more necessary than ever.

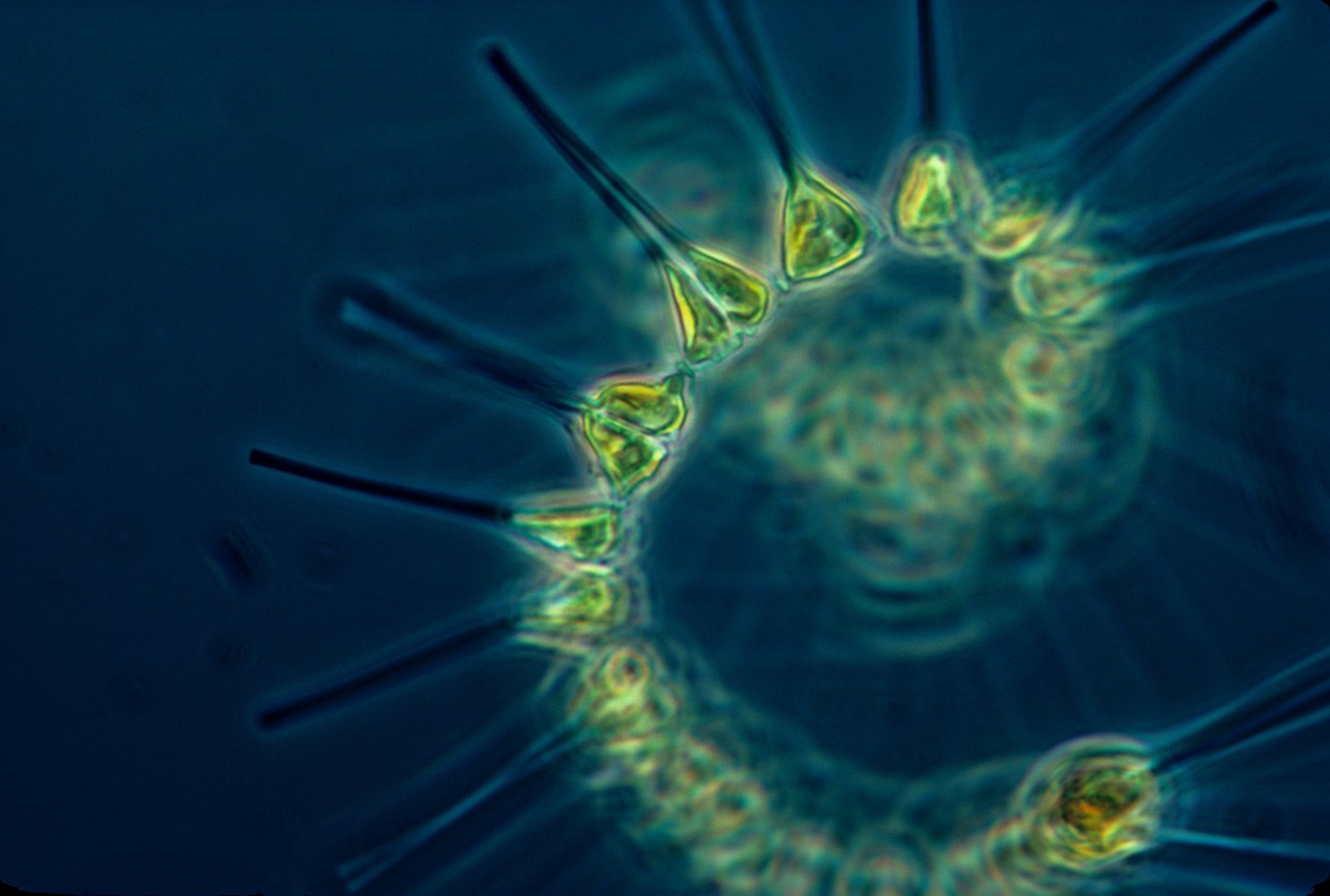

However, the use of mass public transportation poses a very serious problem for the transmission of respiratory diseases, such as SARS 2 Covid-19, smallpox, or the common flu. Enclosed spaces with a large number of people, where the air is not properly renewed, are the place of greatest transmission of this type of diseases.

This is because the rail air conditioning systems currently used were not designed to deal with these problems, and the air conditioning of public transport is not practically exchanged with the outside. The case of high and medium speed trains is even more complex. In this type of train, due to the speeds reached, the railroad is hermetically sealed; as if it were an aircraft. For this reason, it can be said that the current technology used for the design of air conditioning systems has become completely obsolete.

In addition, in Spain, and other European countries, new legislation is being passed regarding air quality, which is why players in the transportation sector need to upgrade their air conditioning systems to meet these new regulations. There are similar initiatives in the United States, Canada and Asia.

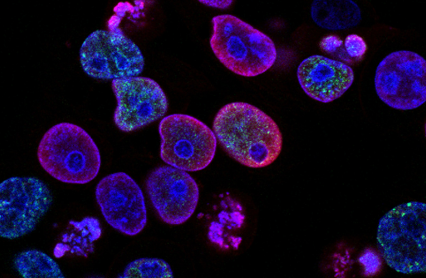

Apart from the use of the mask, the use of ultraviolet light and oxidation by photocatalytic means have also been mentioned as mitigation methods, and even the use of plasma generated by ionizers has been mentioned as another possible mitigation technique to sterilize the air in the HVAC system.

At bottom, there remains an obvious issue here. There are two basic ways to mitigate the possibility of infection in rail transport. One is to exchange outside air, lowering carbon dioxide levels to below 800 parts per million. Since this is virtually impossible to obtain, the other way to mitigate the likelihood of infection is to sterilize the air. That is, if we cannot reduce the proportion of aerosols in suspension in the air due to the lack of recirculation, what we can do is to sterilize those aerosols so that when they are breathed in again this does not lead to the transmission of diseases.

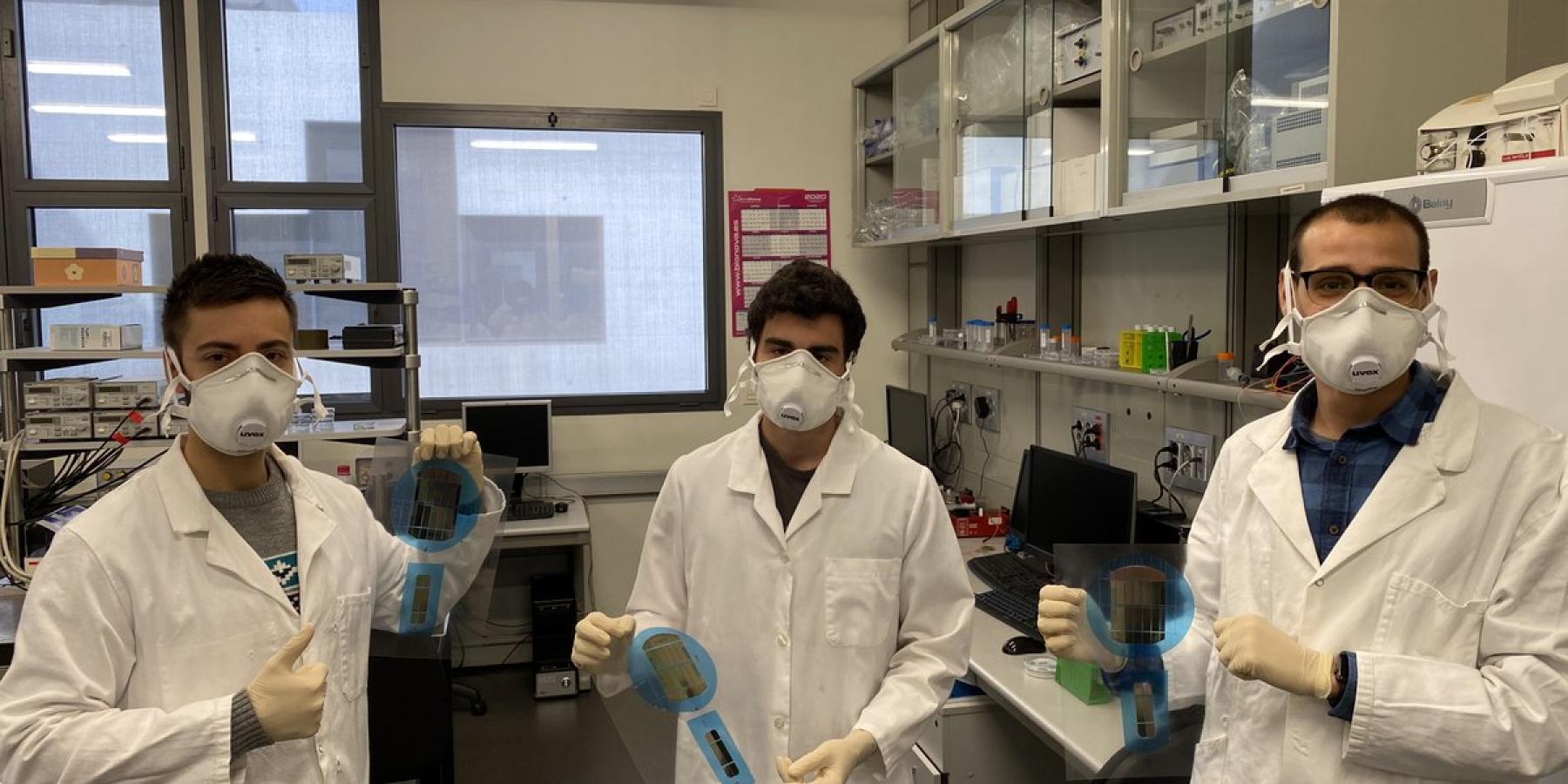

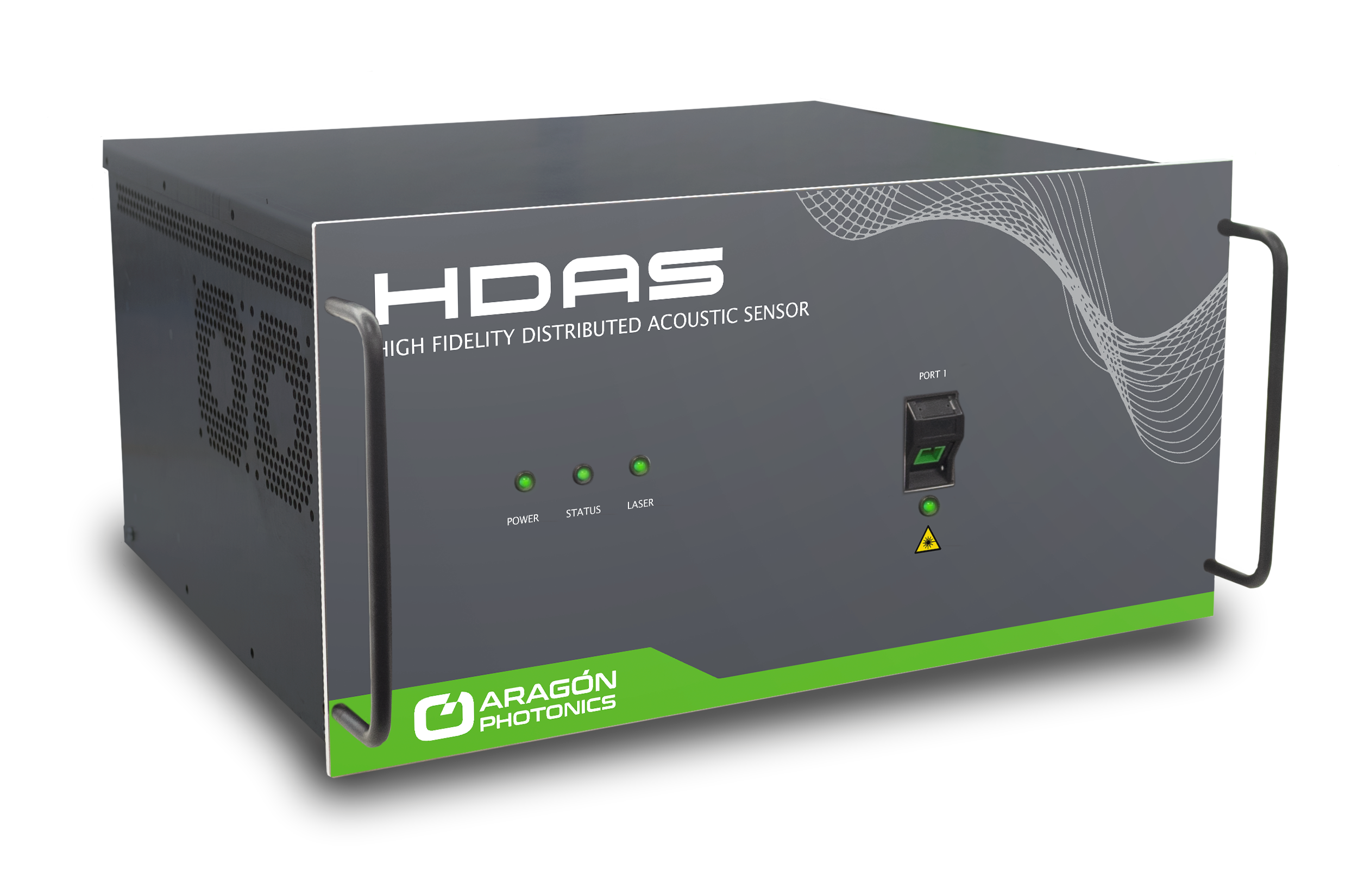

TRAIN SCS (Safe Climatization System) develops a new product, non-existent in the market, which allows the sterilization of viruses and bacteria as well as air quality monitoring

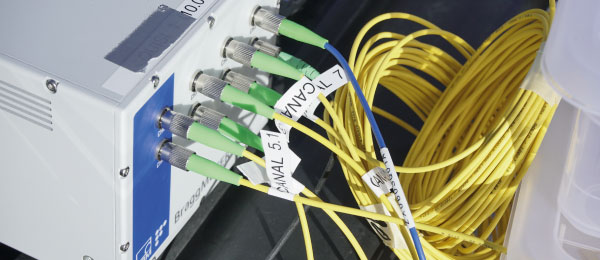

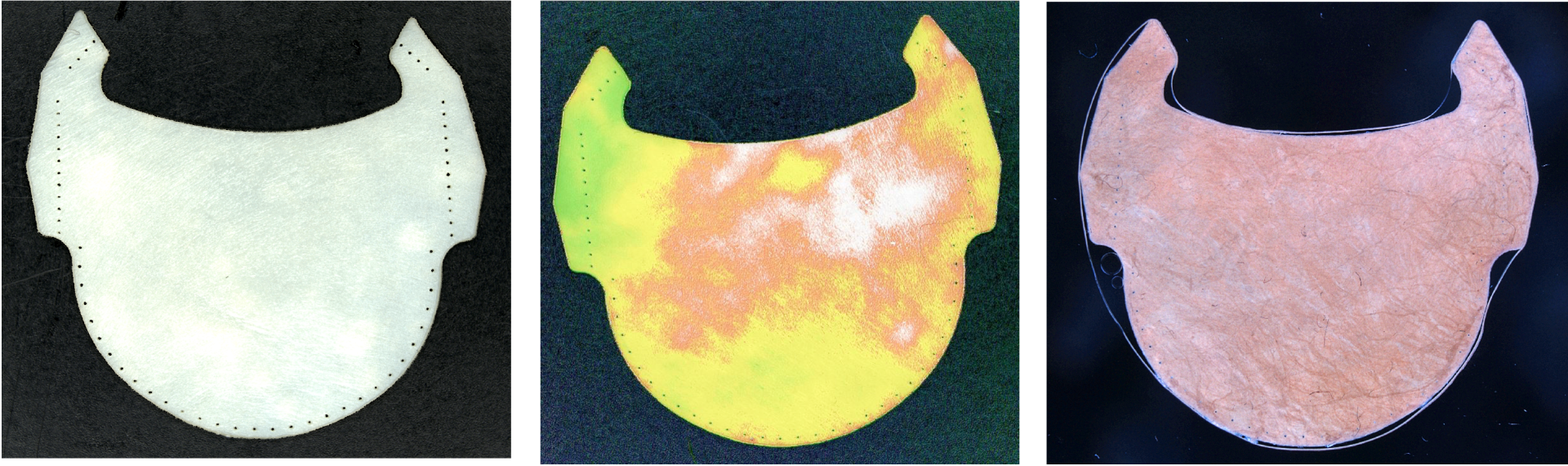

In this context, the TRAIN SCS (Safe Climatization System) project is developing a new product that will allow not only the sterilization of viruses and bacteria, but also the monitoring of air quality for passenger vehicles and railroads through the use of ultraviolet C (254 nm) irradiation inside the air conditioning duct of trains.

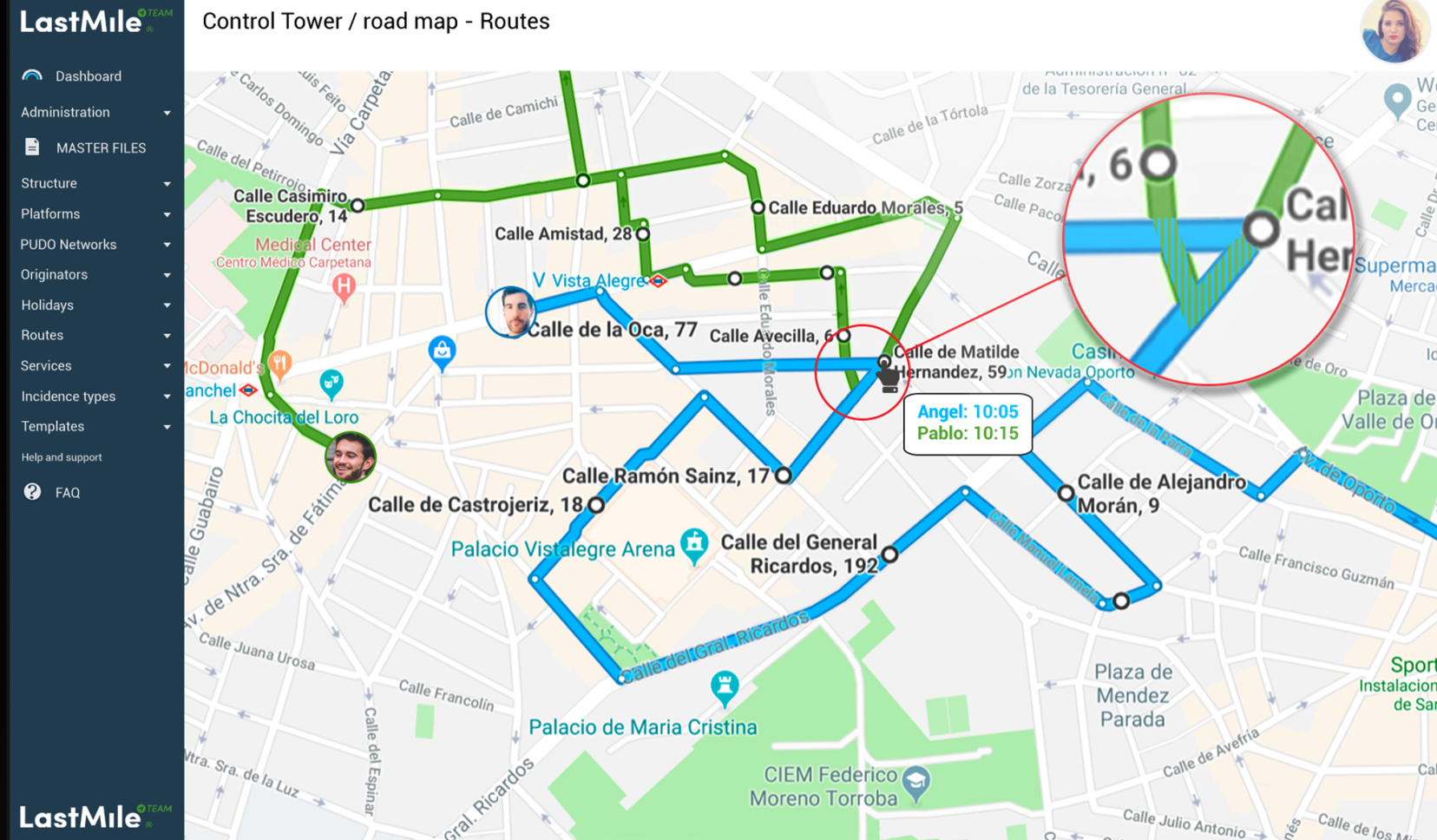

The system also includes sensor probes for real-time process monitoring, providing full traceability of the process and system maintenance. Algorithms generate composite indices that report air quality (IAQ) and infection probability (IPR) with gas concentration values from sensors in the passenger units.