Complete and transversal predictive maintenance system for the rolling mill of a steel plant

The SMARTFAB project is a research project led by the Spanish companies Celsa, Artelnics, T2C and EMIG with secpho coordination.

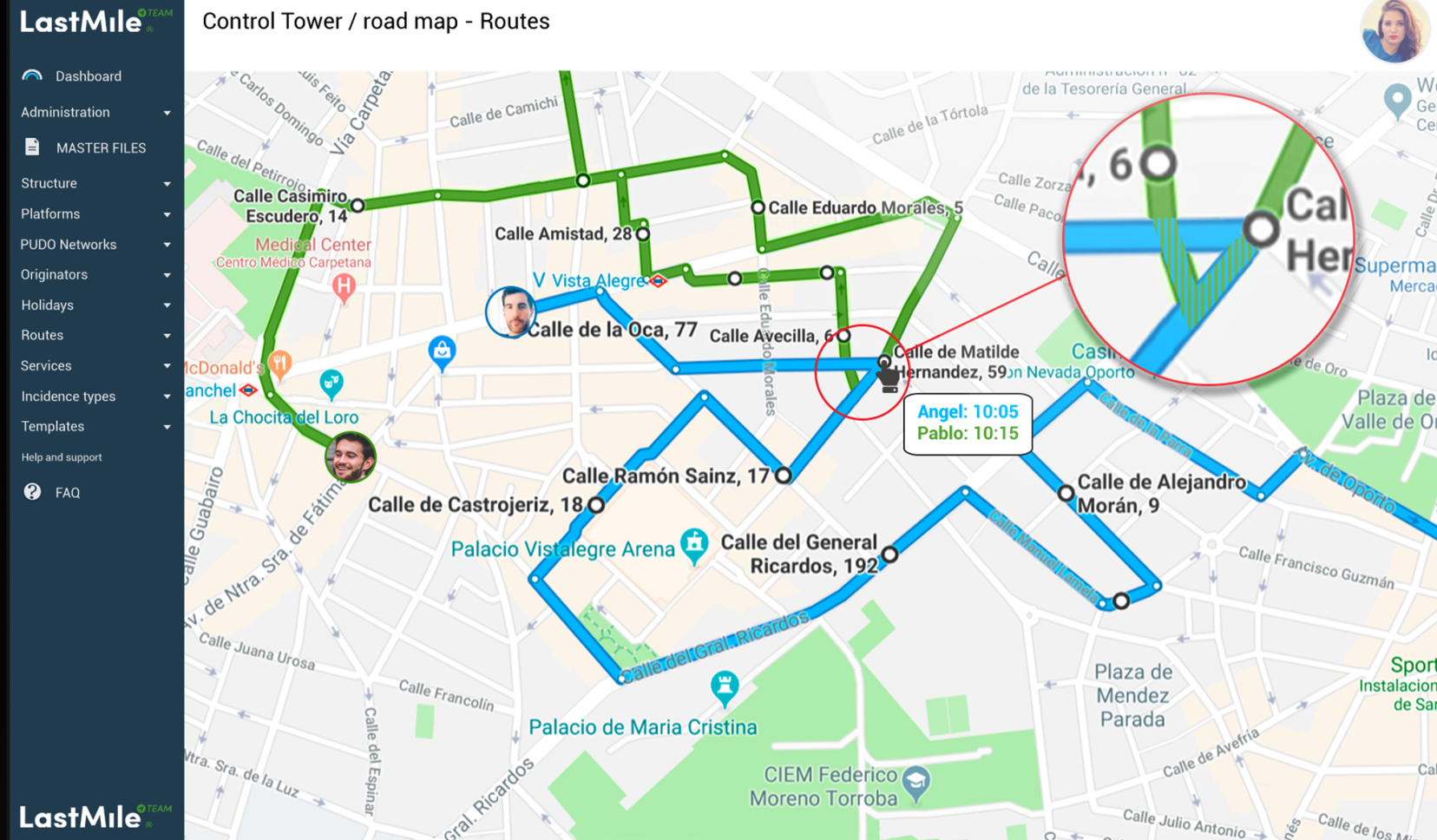

The project seeks through artificial intelligence to detect possible deviations in the processes, which allows detecting failures in the plant before they occur.

The initiative has received funding from the Ministry of Industry, Trade and Tourism corresponding to Next Generation EU funds, canalised through the support programme for Innovative Business Groups, whose objective is to digitalise industry.

There is no standard predictive maintenance system for rolling mill lines because the process on each line is unique.

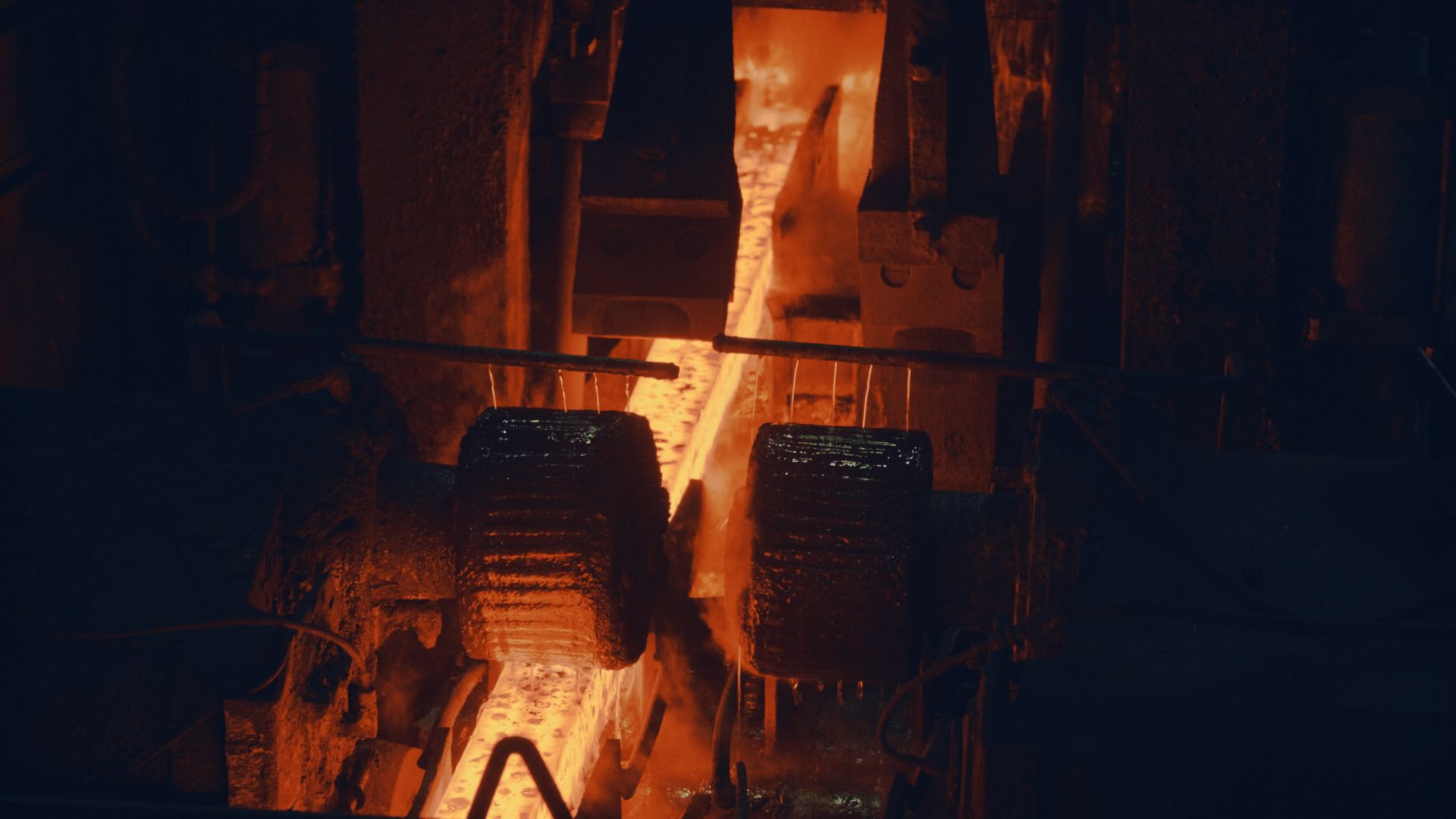

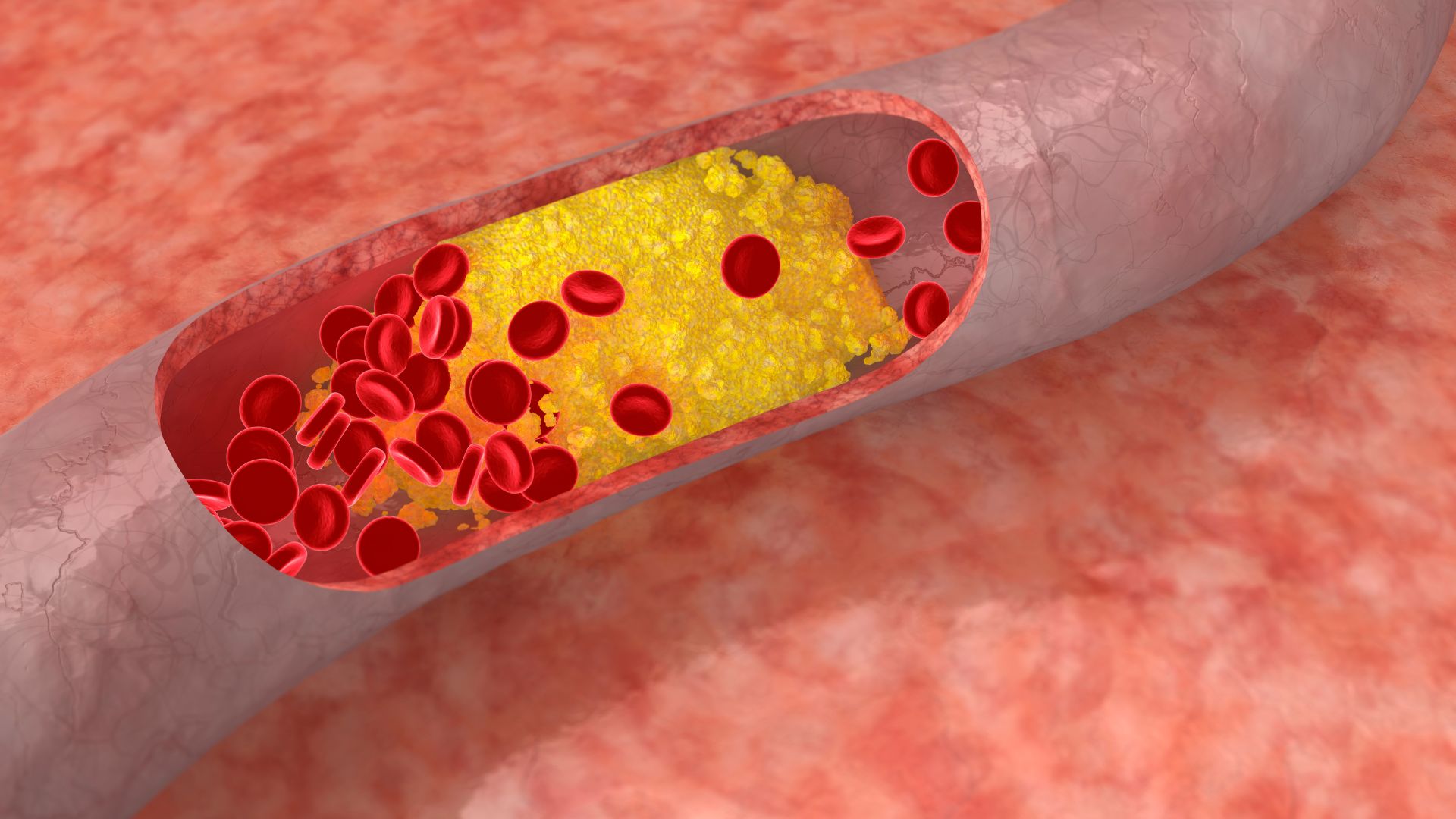

Rolling is one of the last steps in the manufacture of steel for construction and consists of the plastic deformation of steel ingots or billets. It is carried out in the so-called rolling mills, by means of the mechanical action of two rolls that, rotating at the same speed and in opposite directions, exert a pressure that achieves a reduction in the cross-section of the material.

The process in each rolling line is unique, as each furnace, box, etc. is different. Given this casuistry of the industry, there is no standard predictive maintenance system for rolling lines and an ad hoc one has to be created.

Research investigates unique and innovative algorithms because a novel predictive maintenance system has never been created before

Due to the types of processes in the industry – hot processes – and the great variability of the casuistry of the environment and of the production itself, the SMARTFAB project seeks through artificial intelligence to detect possible deviations in the processes, which makes it possible to detect failures in the plant before they occur. It also predicts the operation of the systems, which makes it possible to know when plant maintenance is necessary and to plan it in time. All this provides real-time, detailed knowledge of the plant’s status.

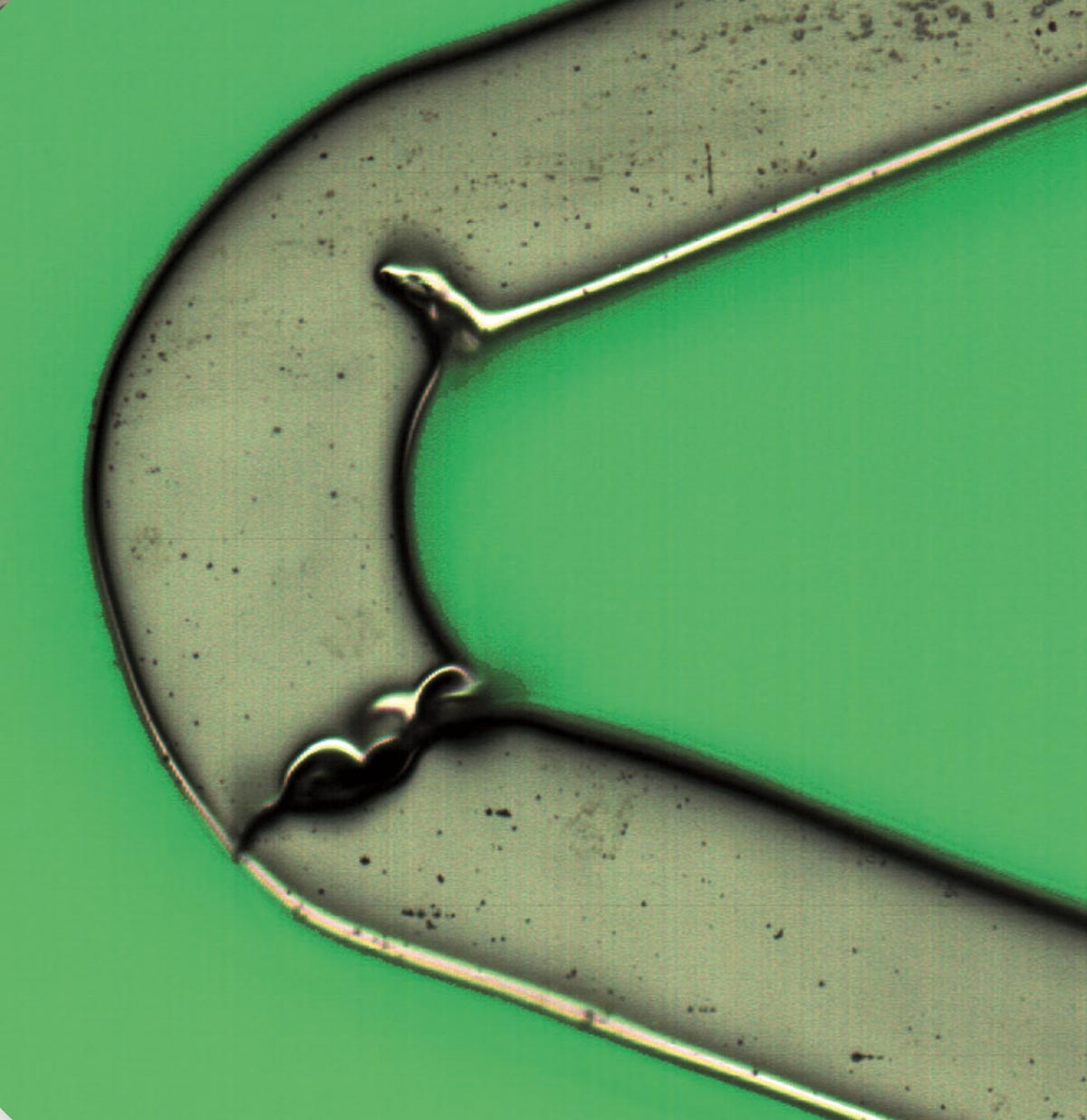

The research also investigates unique and innovative algorithms because a predictive maintenance system for a rolling mill line has never been created using the variables used in this project. In particular, data from the furnace, the rolling mill and the billet at different stages of the process have been used.