Q LEAF IN VITRO

Coronary valves made from animal heart tissue much more efficient and durable

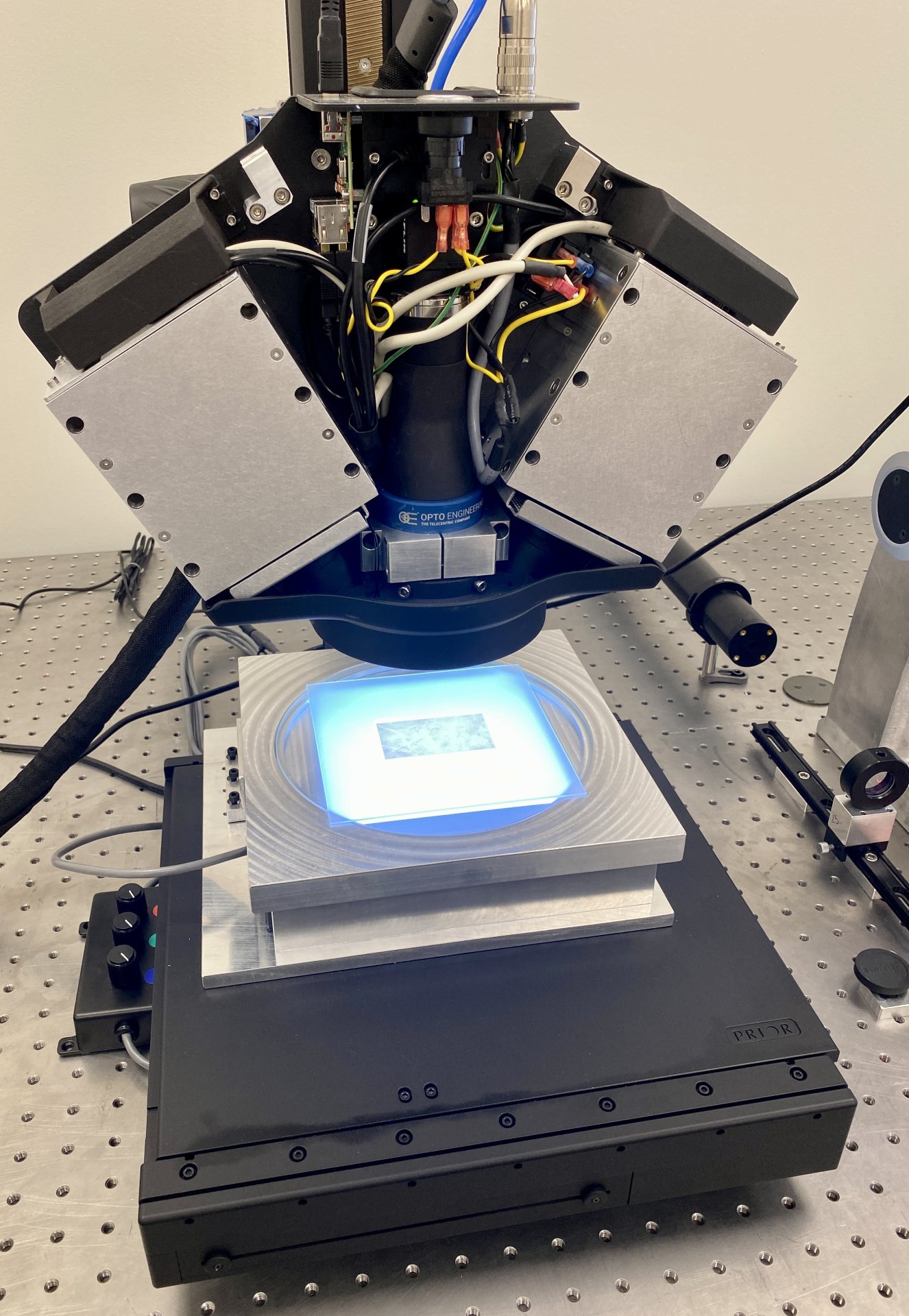

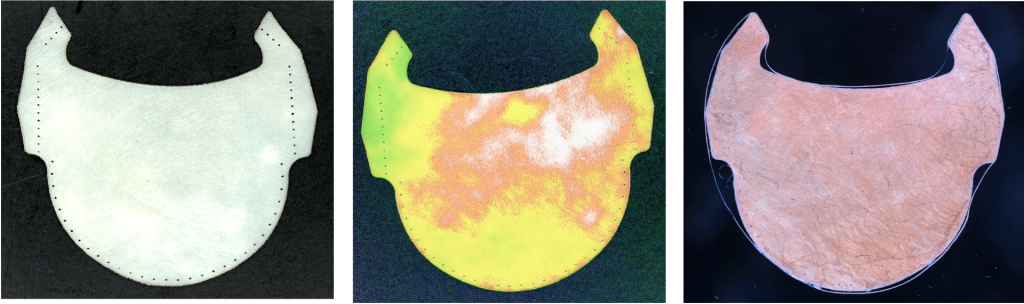

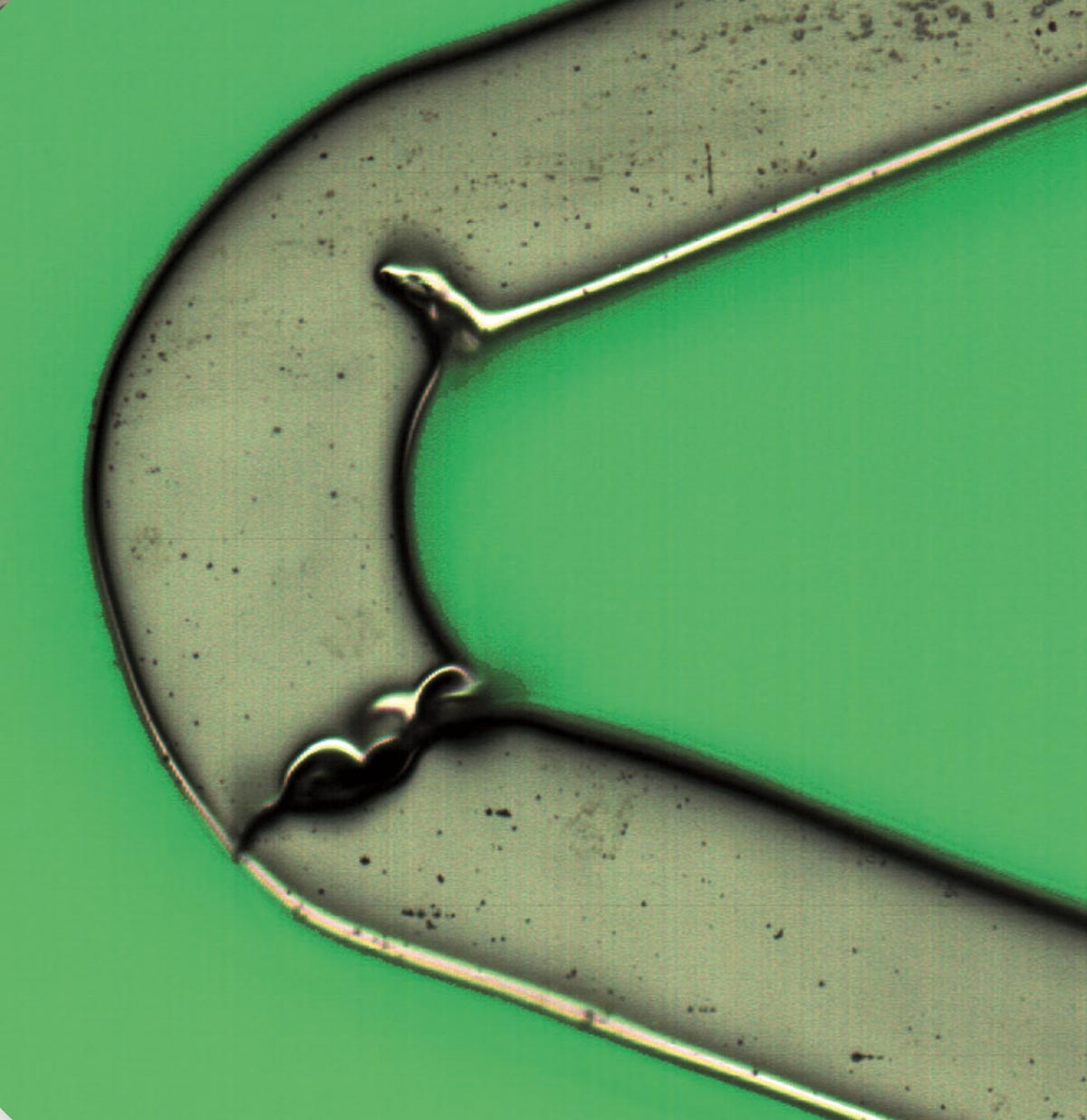

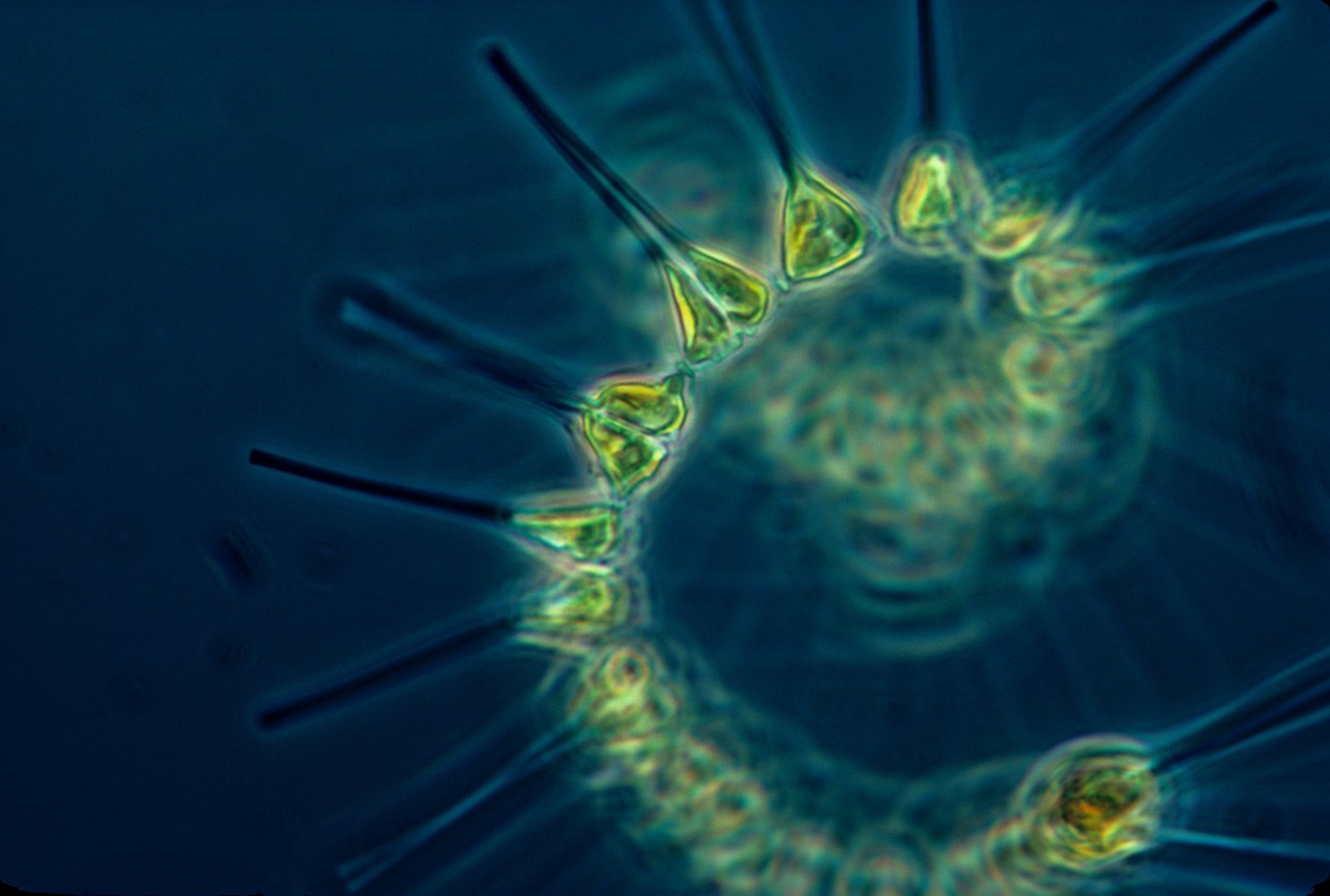

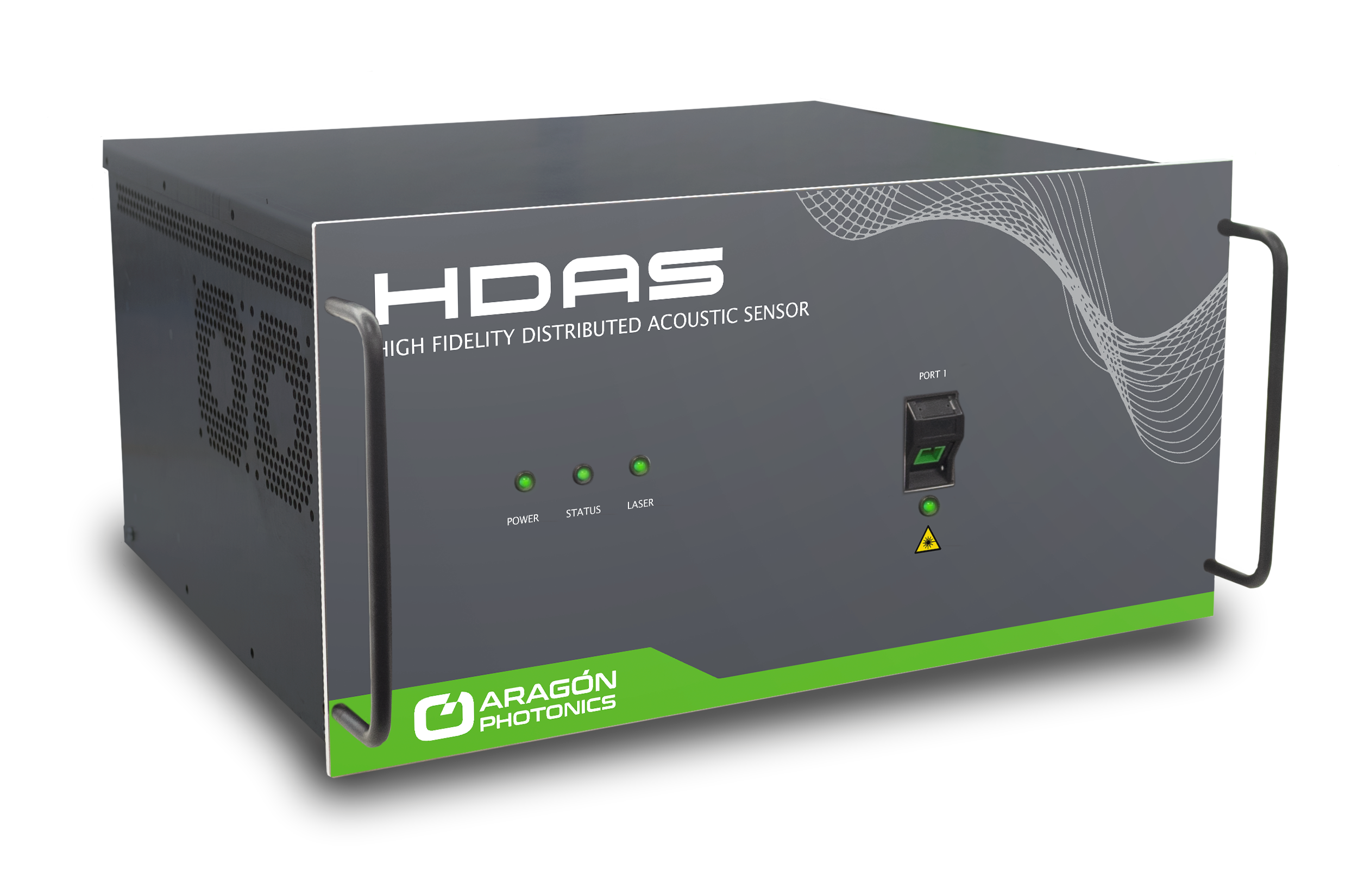

Q leaf technology, based on advanced optical sensors, automates and optimizes the selection of pericardial tissue leaflets. This highly accurate and efficient process improves the mechanical functionalities of the leaflets, thereby extending the lifetime of bioprosthetic heart valves.

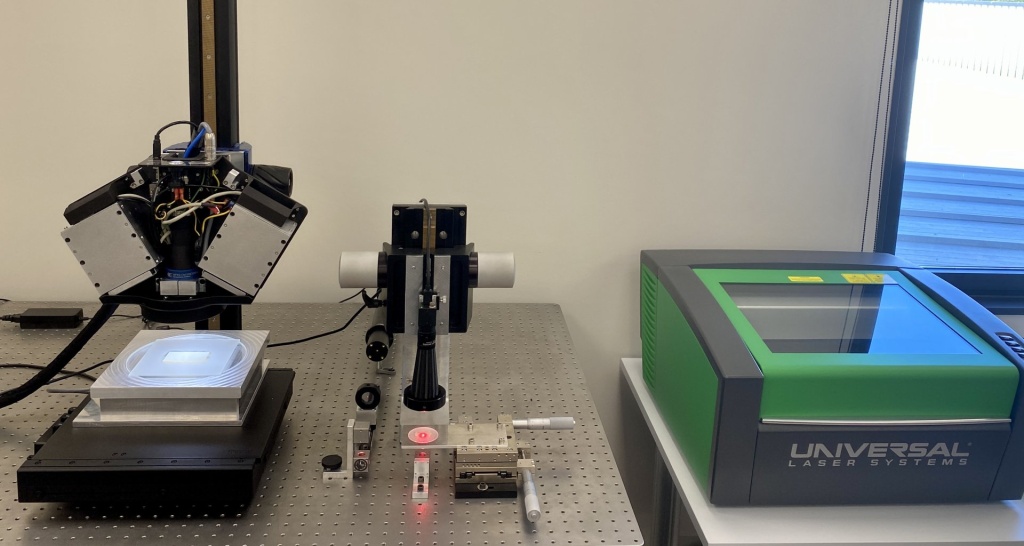

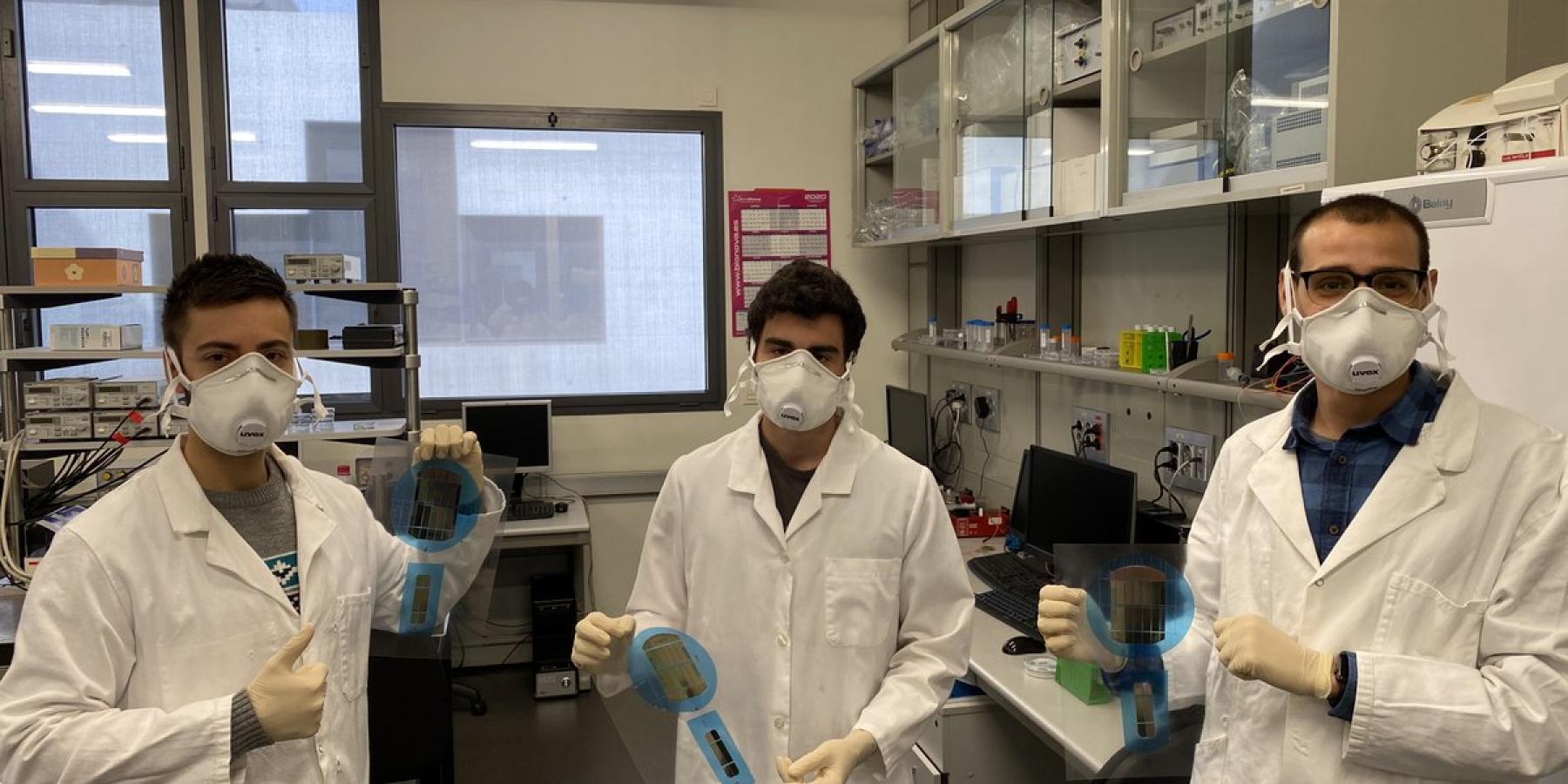

LVD Biotech, Sensofar Medical, UPC-CD6 and Stimulo have collaborated in the third phase of the project, Q LEAF IN VITRO, which has created an automated leaflet manufacturing cell focused on optimizing the process and reducing production costs.

The initiative has received funding from the Ministry of Industry, Trade and Tourism corresponding to Next Generation EU funds, canalised through the support programme for Innovative Business Groups, whose objective is to digitalise industry.

In 2018, more than 10 million stents and 100,000 coronary valves were successfully implanted worldwide, and the forecast for this market is to continue to grow.

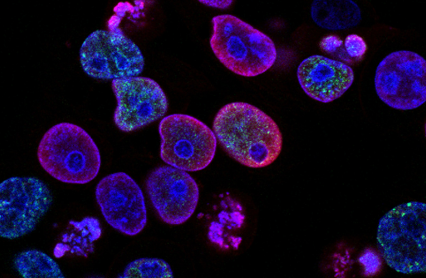

Heart disease, being the leading cause of death worldwide, demands innovative strategies to improve prevention and treatment. In this context, implantable devices, such as bioprosthetic heart valves, have gained prominence. However, current limitations in the durability of these devices pose significant challenges.

2020 witnessed the successful global implantation of more than 12 million stents and nearly 300,000 heart valves. With the projected global cost of treating heart disease exceeding $70 billion by 2030, the need for more effective and affordable solutions is evident.

Valvulopathies, particularly severe aortic stenosis, represent a critical challenge. Valve replacement surgery has been an effective solution, but structural degeneration and hemodynamic dysfunction of bioprosthetic valves, detected as early as five years post-implantation, raise concerns.

The combination of Q leaf technology and the automated manufacturing cell could fundamentally change the way these important medical solutions are produced and used

The project not only seeks to improve the quality of bioprosthetic heart valves, but also aims to make these improvements globally accessible.

In addition to technological innovation, the project has created an automated leaflet manufacturing cell focused on optimizing the process and reducing production costs. Este enfoque no solo impulsa la eficiencia sino también potencialmente democratiza el acceso a mejoras significativas en la calidad de las válvulas cardíacas.

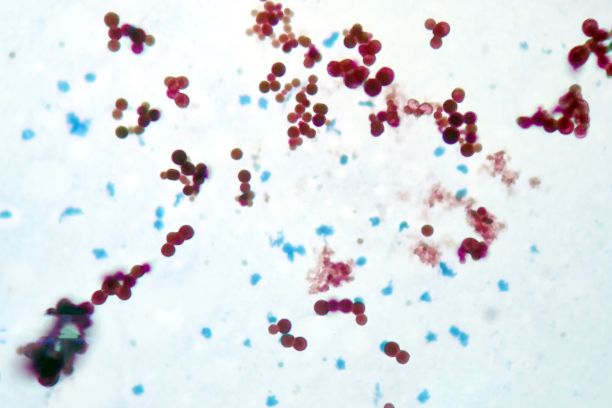

As a key part of the research, a comparative in vitro study has been conducted using TAVI-type heart valves. This study, designed to evaluate the Q leaf technology under real operating conditions, has provided robust and quantifiable results on the efficacy of this innovation.

The stages of the study included the manufacture of TAVI valves and the preparation of leaflets using Q leaf technology and conventional methods. In addition, hemodynamic efficacy and durability tests have been performed, using criteria established by the VARC (Valve Academic Research Consortium) group. This comparative approach allows evaluation of potential improvements in terms of durability and hemodynamic functionality.

Sensofar Medical brings expertise in advanced optical technology, the UPC-CD6 center contributes with its R&D and prototyping capabilities in the field of optical engineering, while LVD Biotech, as a medical device manufacturer, provides a practical perspective and the ability to bring innovations to market.

With the in vitro study underway and the optimization of the manufacturing process underway, the Q leaf project is at the forefront of medical innovation. The promising results of this project will have a significant impact on cardiac care, offering more durable and effective solutions to current challenges in the field of cardiovascular disease.