The project will create a structure with internal sensors that emulates the human nervous system and will be capable of capturing information from its environment.

The landing gear is a fundamental part of aircraft that serves as general support for the aircraft, allowing it to move on the surface, as well as cushioning, absorbing the impact generated by landing, and having the capacity for braking and steering. This fundamental system for aircraft is made up of the wheels, supports, shock absorbers, and the different equipment that an aircraft uses to manoeuvre.

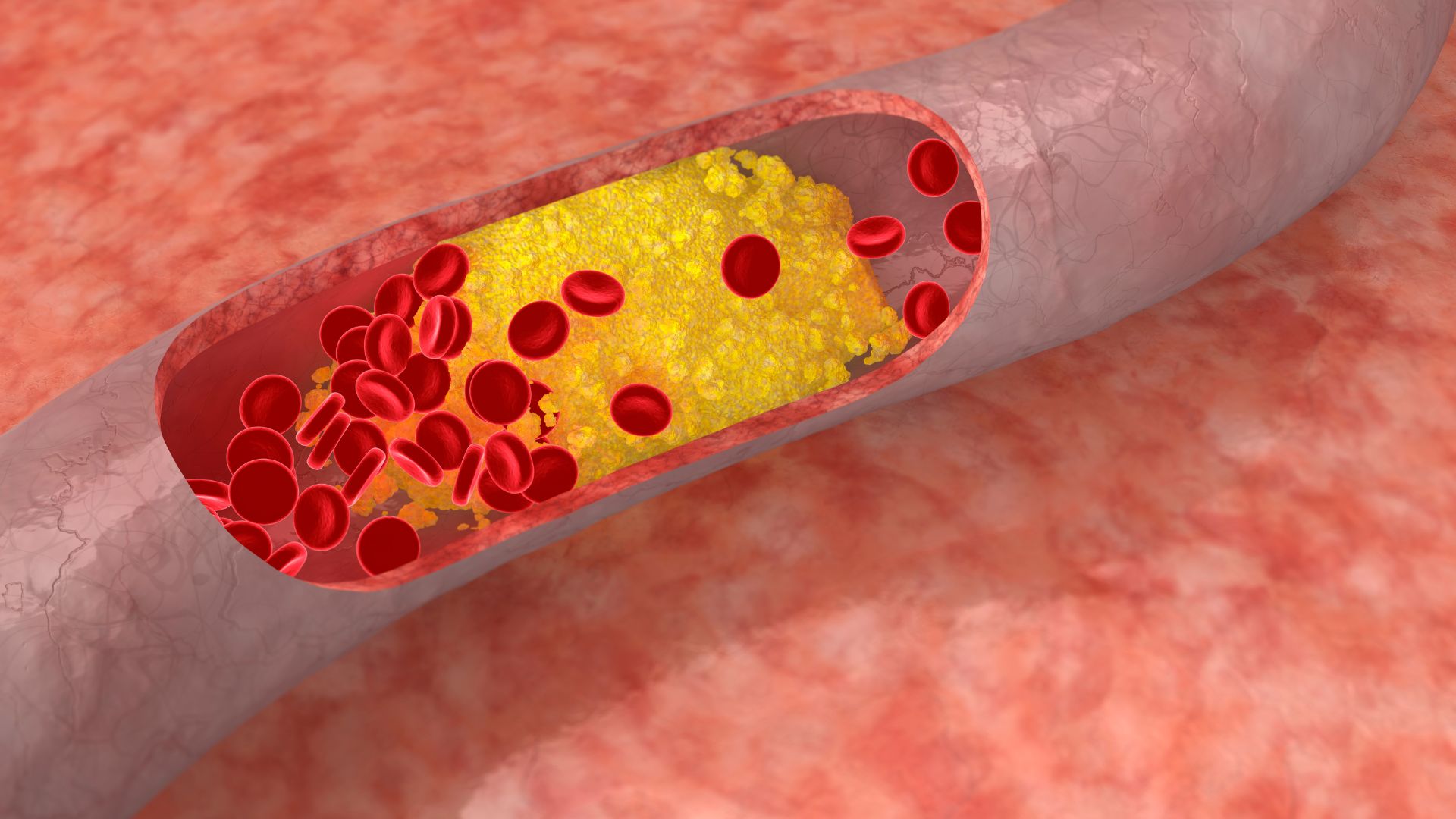

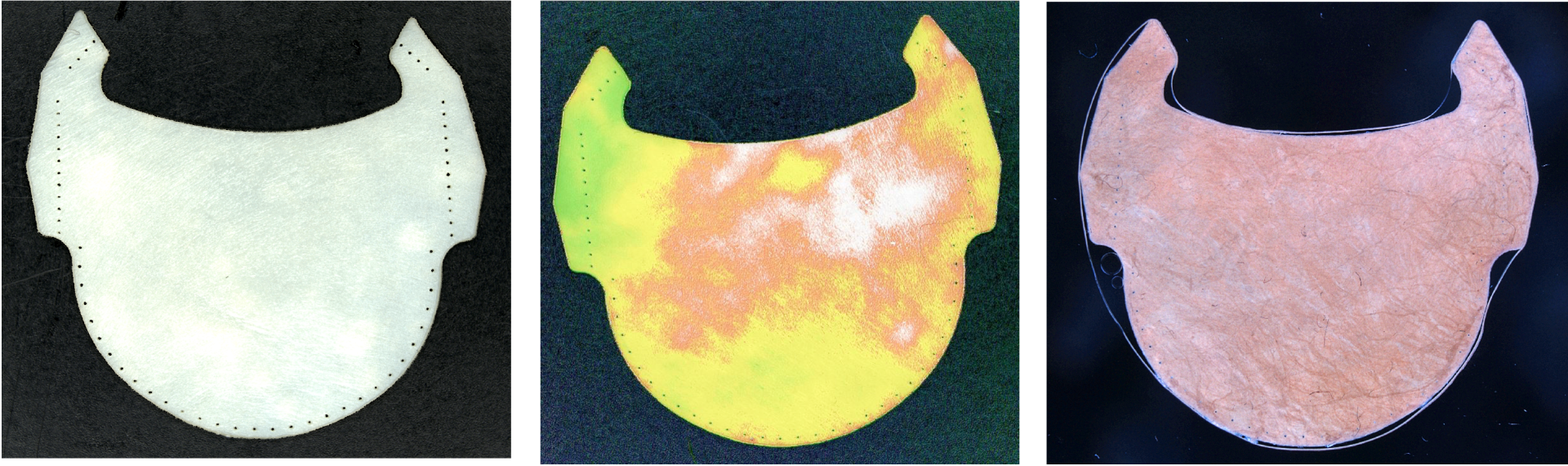

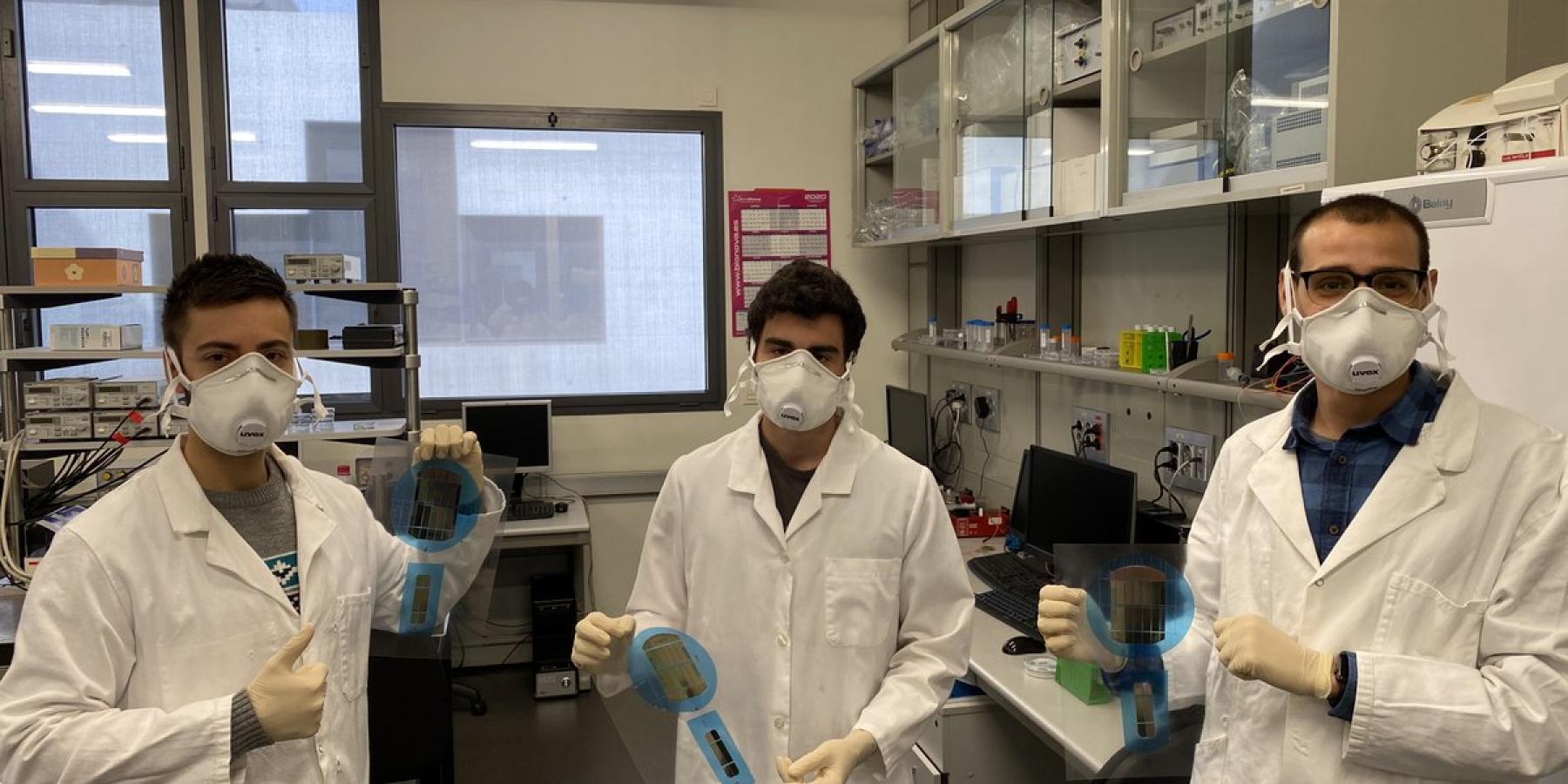

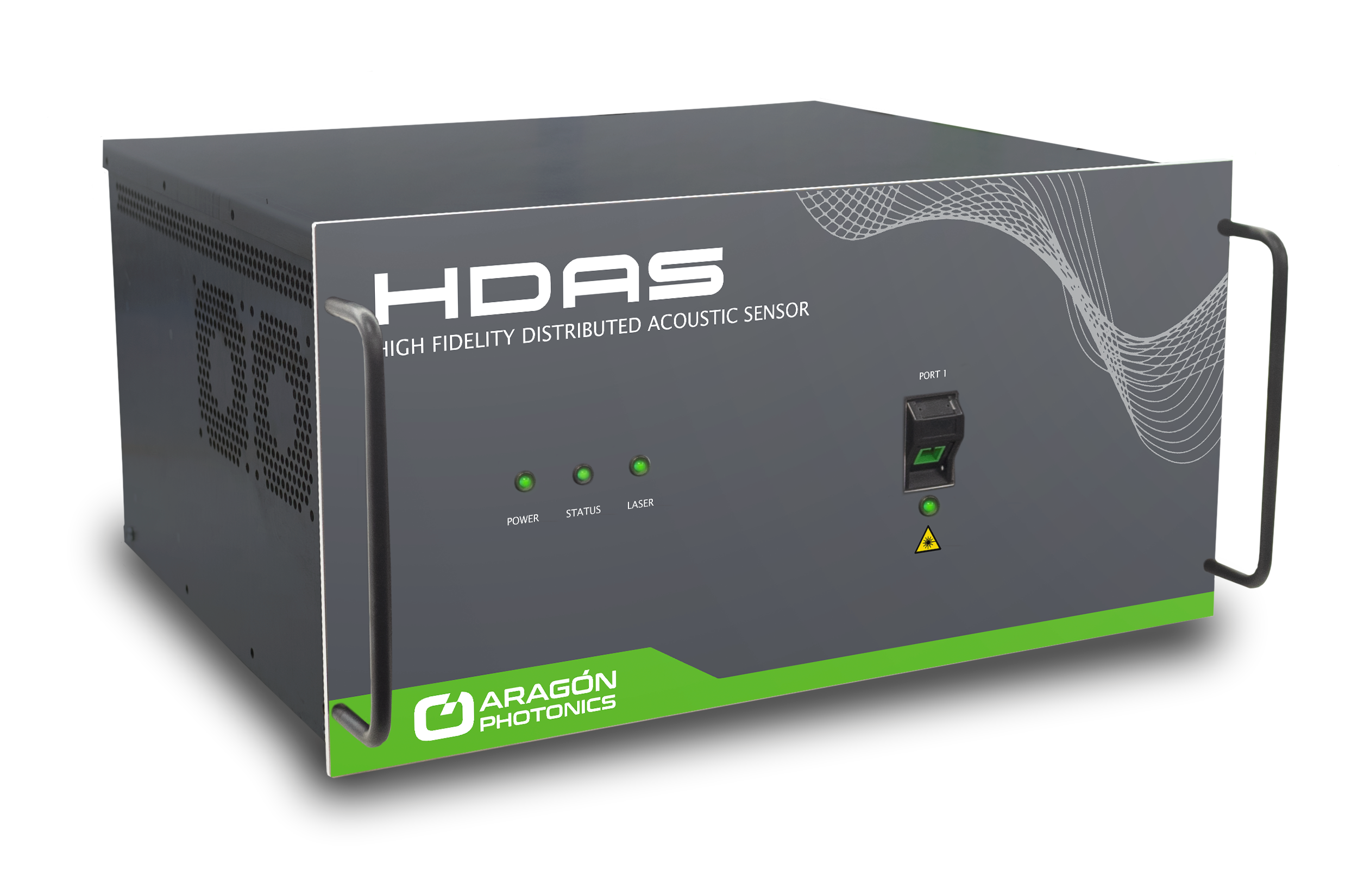

It is essential that all components of the machine function correctly. Nowadays, the monitoring of these structures is done by controlling the external surfaces with which they are in contact. However, one of the main problems of landing gear is the internal micro-breaks, and their control can only be done before or after landing – through non-destructive techniques such as X-Ray, Thermography or, Ultrasound. But at the moment, there is no system that performs a real-time check of the internal parts of the landing gear at the moment of use. And this is where the INSENSE project, which brings together the knowledge in Additive Manufacturing of the Lortek technology Centre, the experience in developing fibre optic sensors of the University of the Basque Country (UPV/EHU) team, and the experience in testing components and materials for high-reliability applications of the engineering company Alter Technology, which will be responsible for validating the design of the prototype.

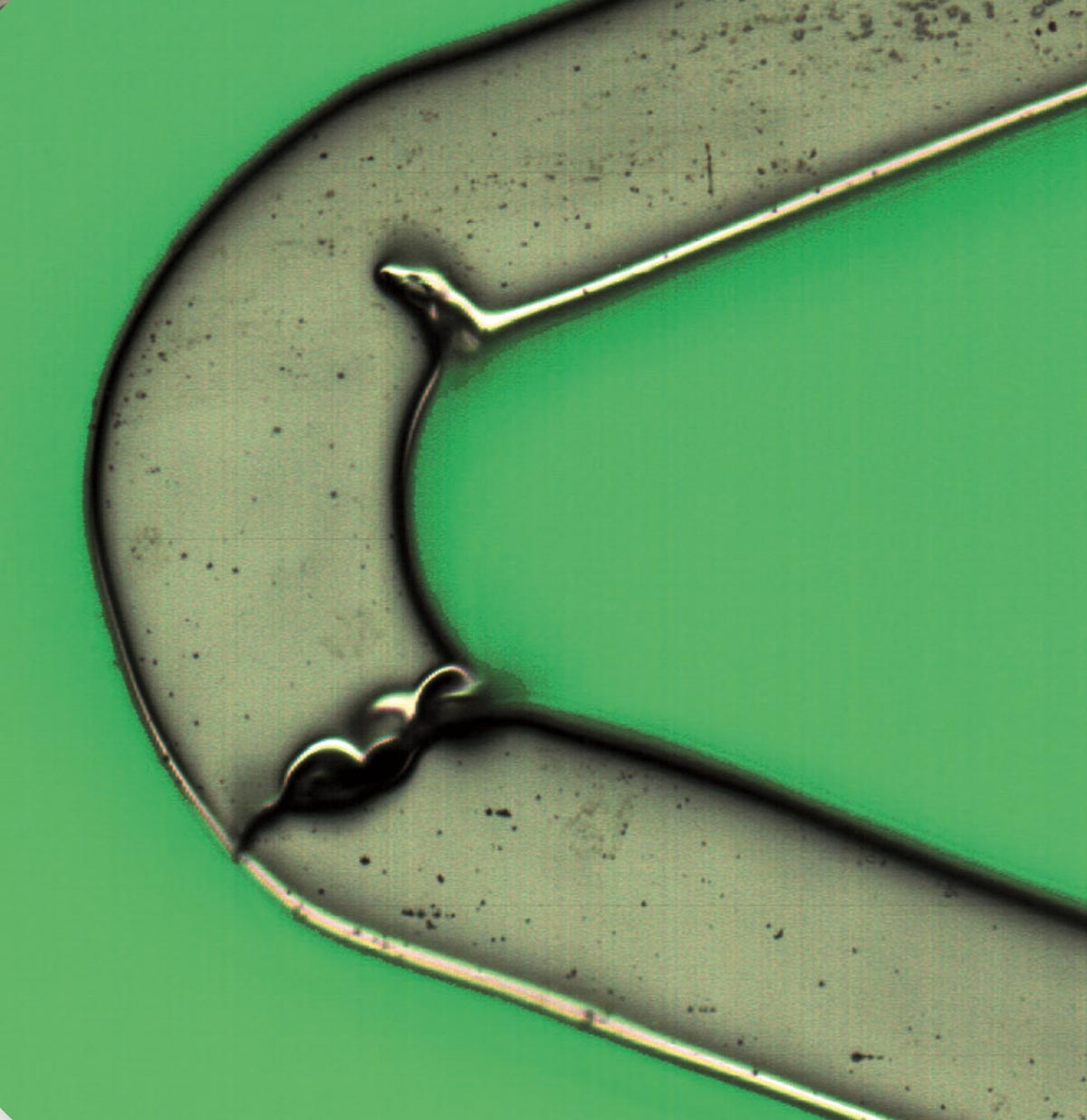

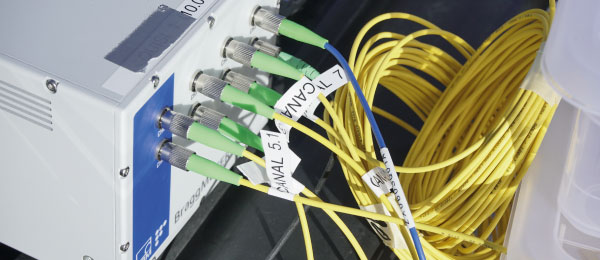

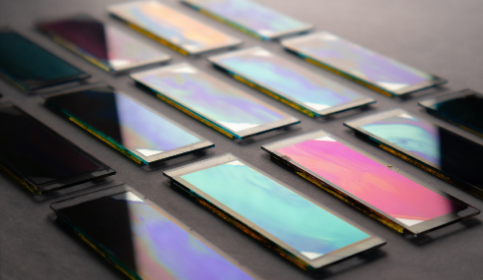

The INSENSE research team is developing intelligent and sensitive parts that could make up parts of the landing gear. To this end, metal parts are being produced using Additive Manufacturing – also known as 3D Printing – into which fibre-optic sensors capable of withstanding the high temperatures reached during the manufacturing process will be strategically inserted. The result will be a structure with internal sensors that emulates the human nervous system. These new-generation parts will have the ability to capture information from their environment, which will allow internal monitoring of the structure.

The development is funded by the Ministry of Industry, Trade and Tourism’s programme of support for Innovative Business Groups in the 2020 call, which aims to improve the competitiveness of SMEs.