PROVIDENTIAL

3D image and Artificial Intelligence to improve construction accident prevention

The European Union has identified the construction sector, in particular, as one of the priority sectors to undergo digitalisation processes in the coming years. Moreover, in Spain, it is the productive sector with the highest occupational accident rate.

In this context, COMSA, Beamagine, UPC and Sensofar Medical are collaborating on the PROVIDENTIAL project to carry out research to improve the digitisation of construction sites and thus ensure maximum worker safety.

The initiative has received funding from the Ministry of Industry, Trade and Tourism and the European Union-Next Generation EU, within the support programme for Innovative Business Clusters, which aims to digitise industry.

The EU has identified the construction sector as one of the priority sectors to undergo digitalisation processes in the coming years.

The construction sector has a series of specific characteristics that do not occur in other sectors and which have a major impact on the prevention of occupational risks. Some of these circumstances can be summarised as temporary work centres with a large number of people working in the same centre, multiple subcontracting of companies or permanent rotation of workplaces, generally in the open air. These circumstances make preventive work difficult, both for the company and for the technicians and workers in this sector.

All this means that the risk on construction sites is high and that construction activity is considered to be highly dangerous. The rates of frequency and incidence of occupational accidents by productive sectors, collected by the Ministry of Labour and Immigration (MTIN), objectively confirm this higher risk in the construction sector. This incidence is confirmed year after year, as can be seen in the historical indices.

Of course, this high occupational accident rate in the construction sector also translates into a very high rate of sick leave with the consequent negative impact on company productivity, as well as costs arising from temporary incapacity benefits borne, directly or indirectly, by companies, mutual insurance companies and the Social Security. In line with this problem, the EU has identified the construction sector, in particular, as one of the priority sectors to undergo digitalisation processes in the coming years.

PROVIDENTIAL combines 3D image technologies and Artificial Intelligence to prevent occupational hazards in the construction sector.

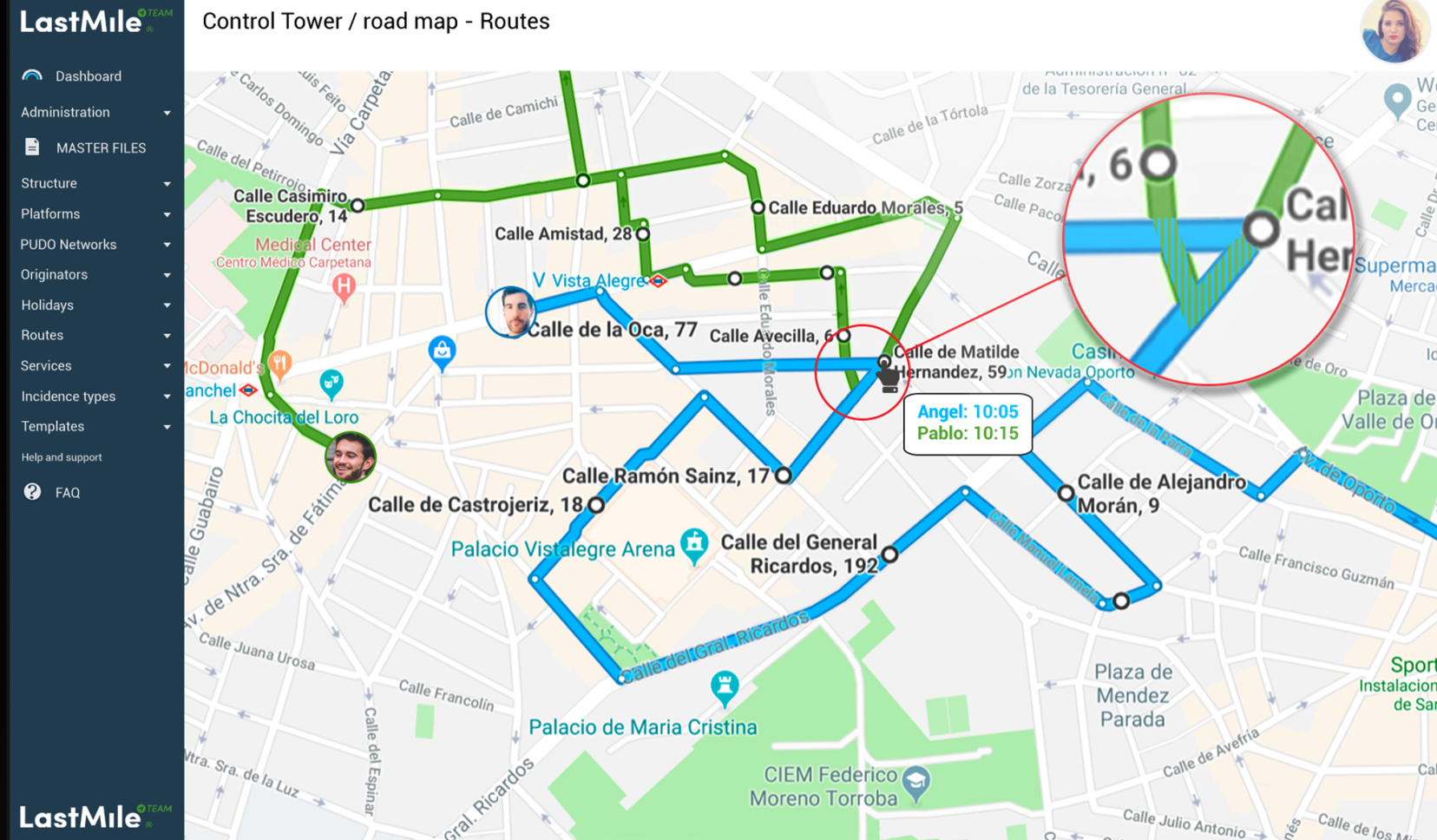

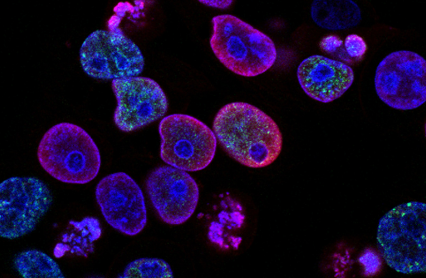

In this context, the PROVIDENTIAL project explores risk in the field of construction by incorporating new 3D imaging and data fusion technologies combined with artificial intelligence (AI)-based processing, in order to optimise prevention, monitoring and inspection procedures at the construction site and thus optimise investment in occupational risk prevention.

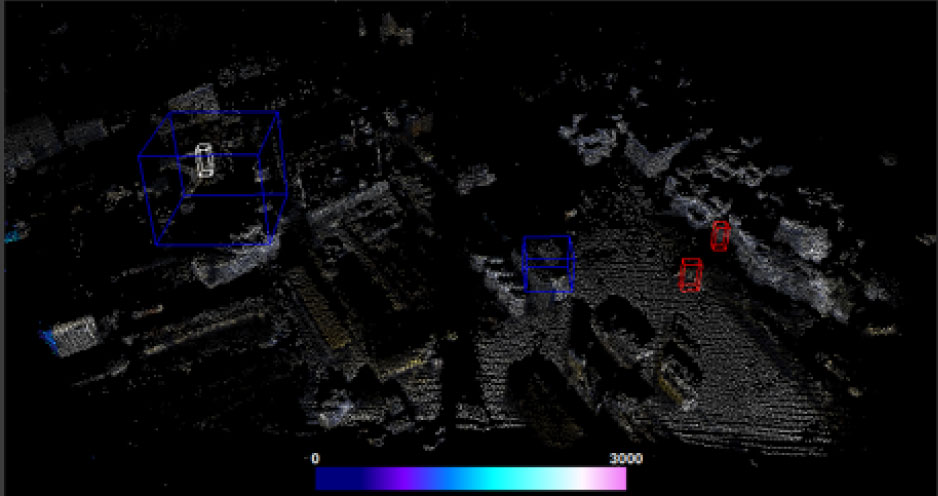

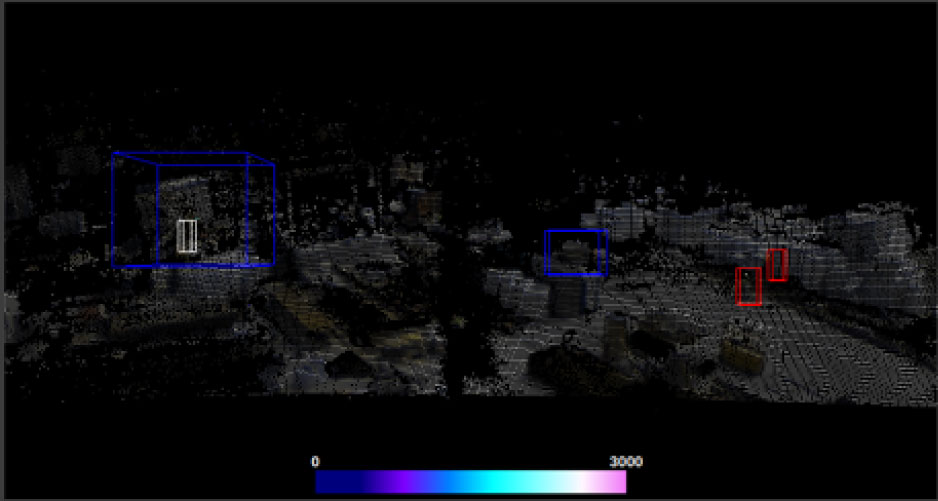

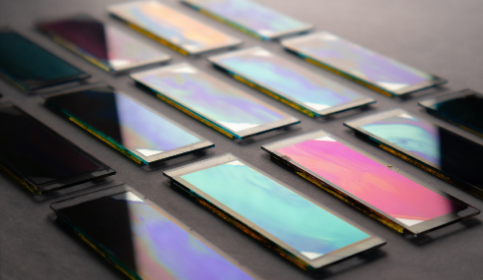

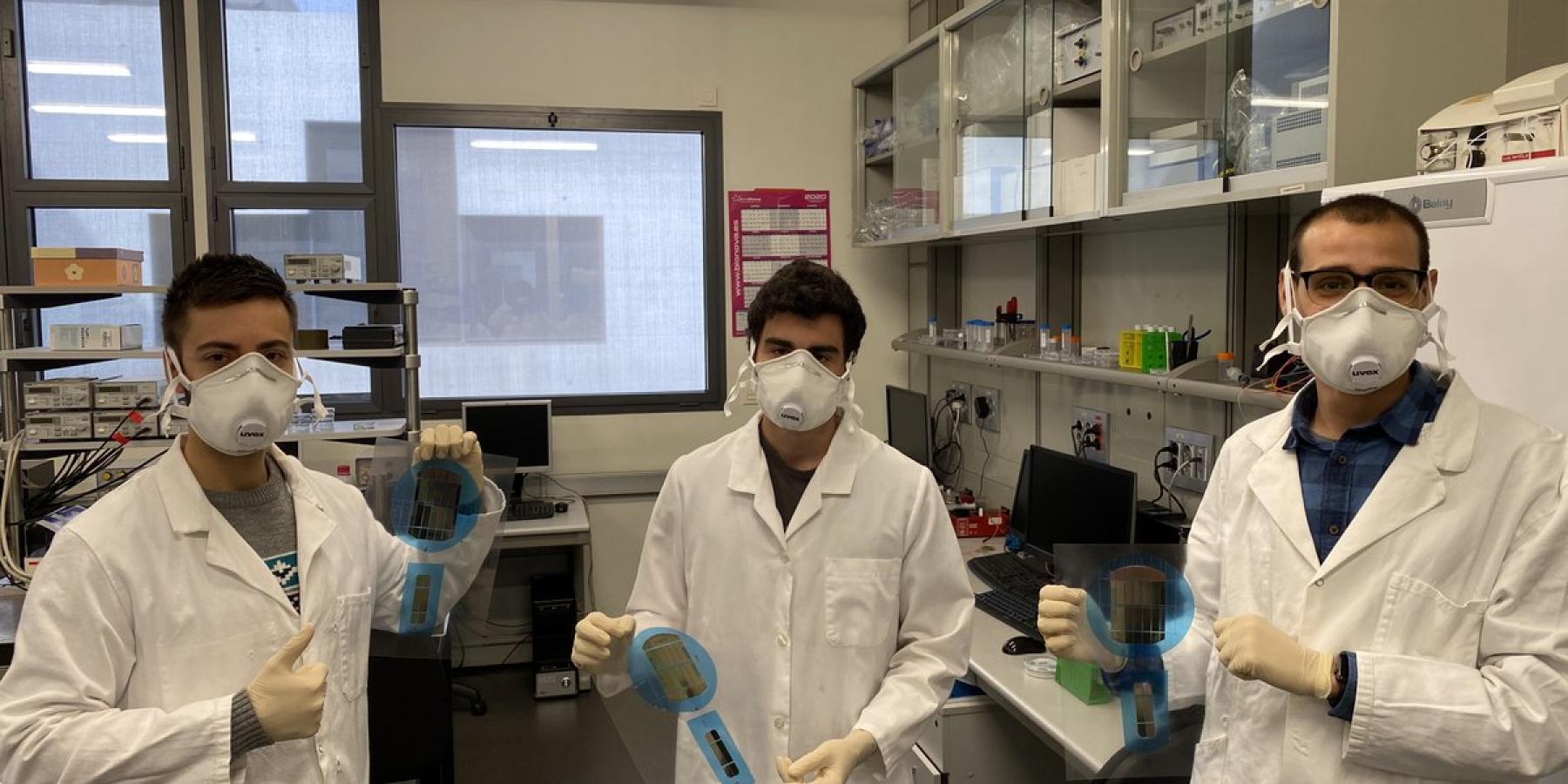

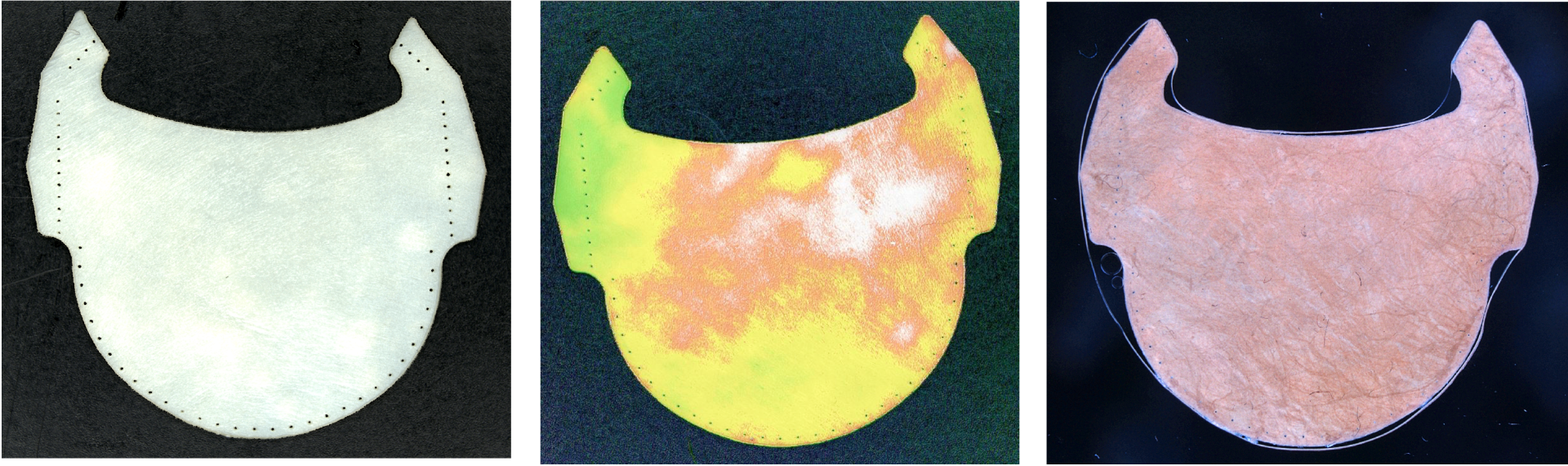

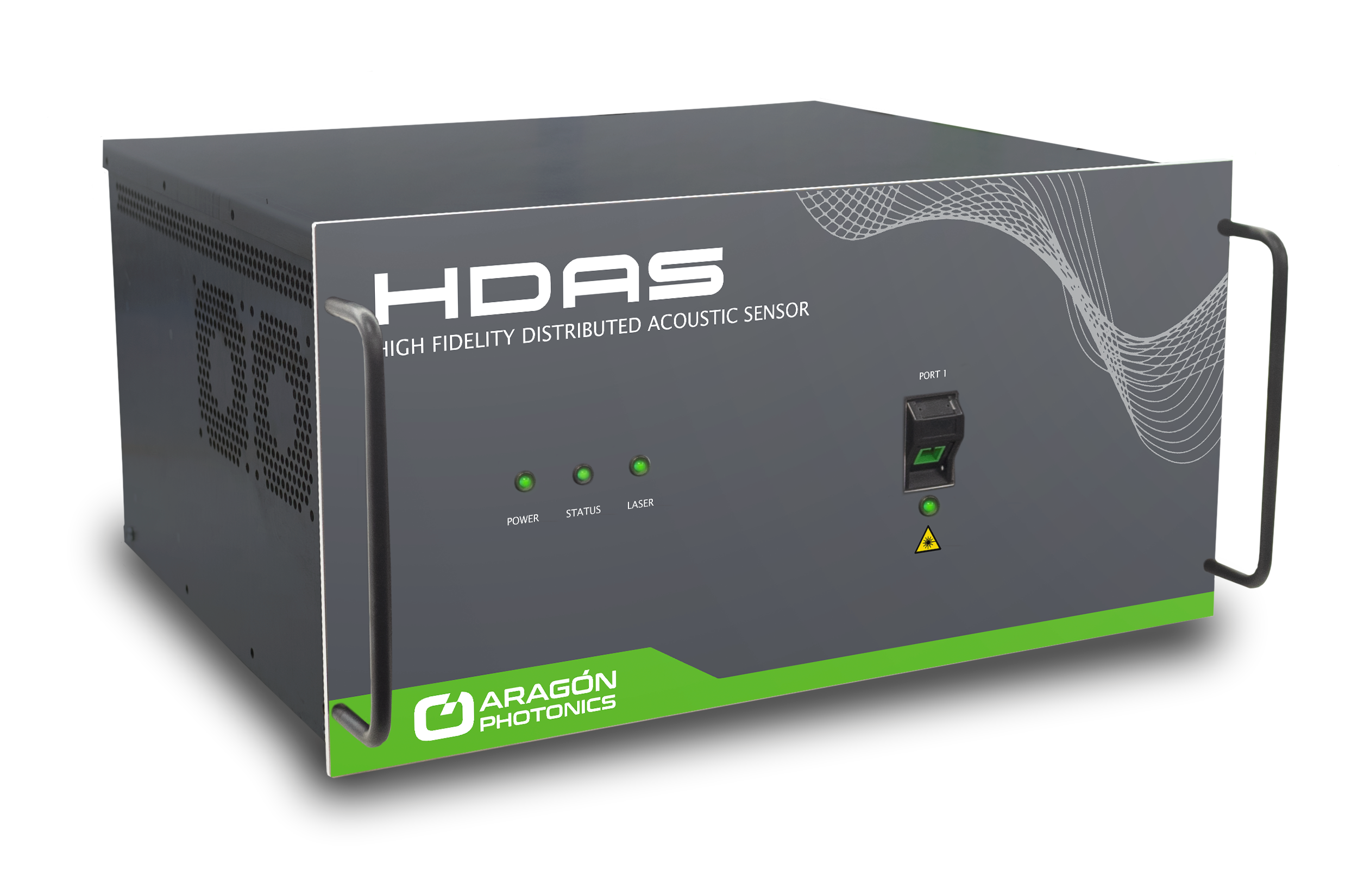

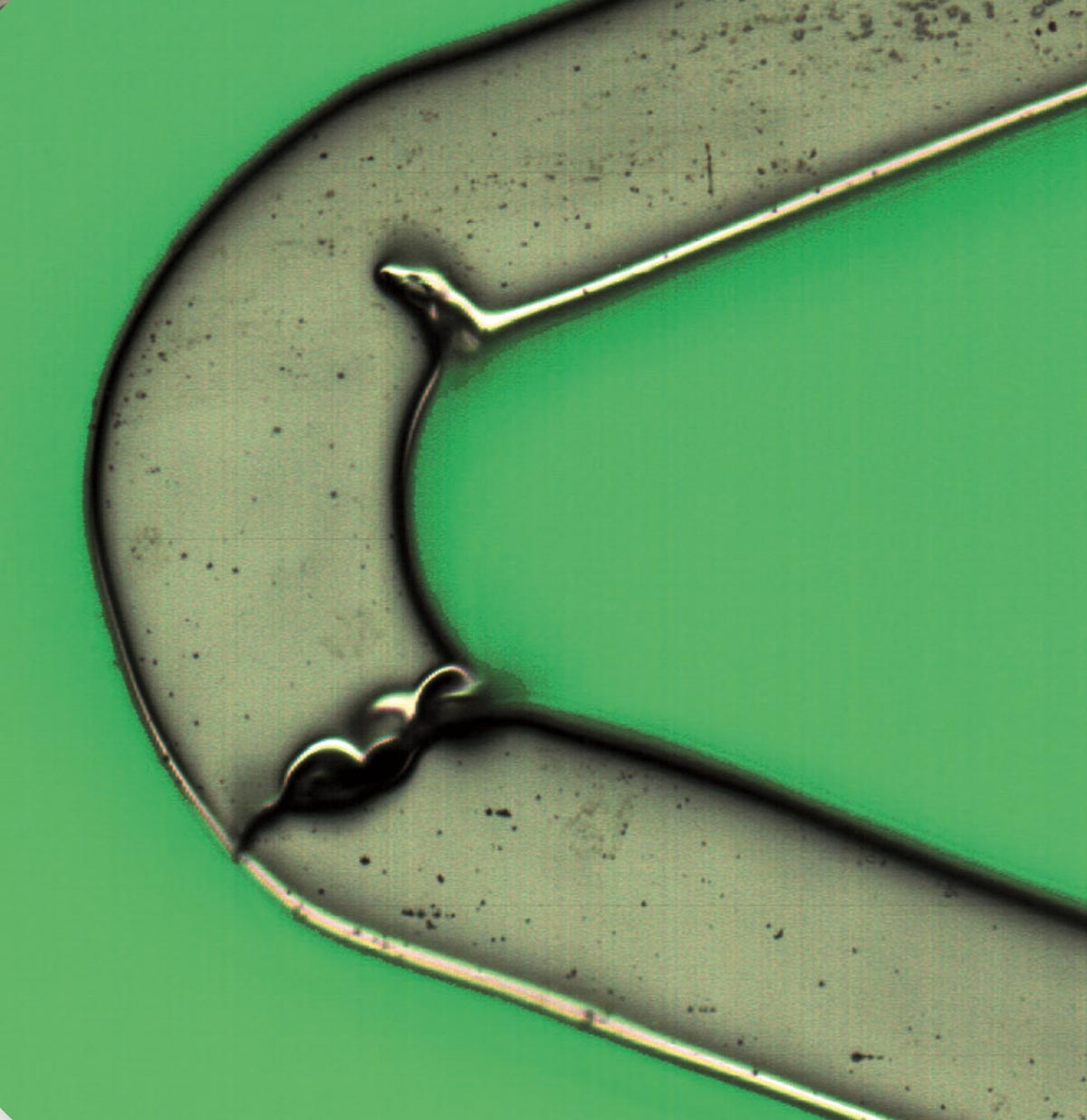

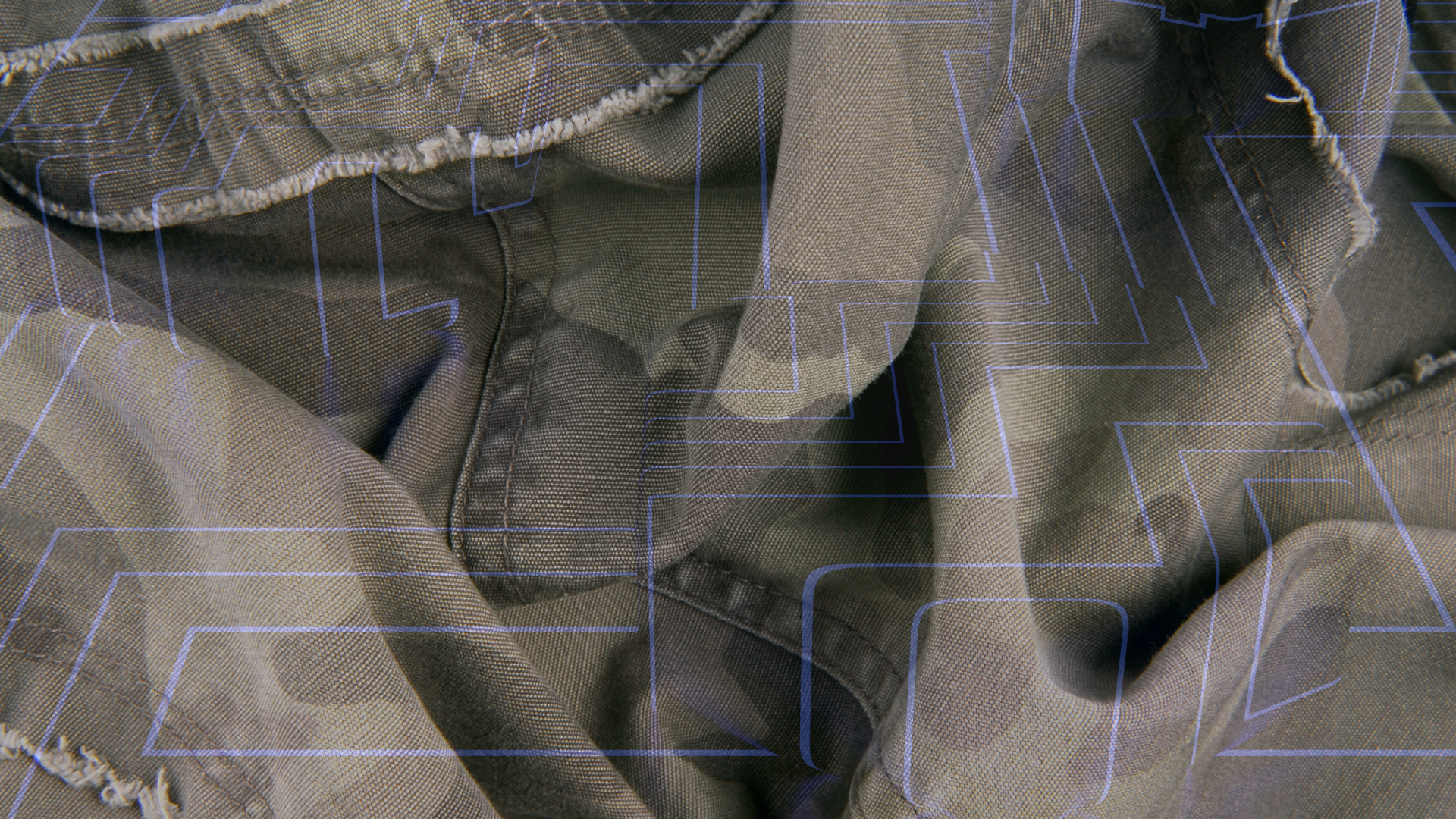

To this end, a combination of sensors including 3D lidar imaging, RGB imaging, and thermal imaging has been selected and implemented to provide sensing capabilities in multiple environments (indoor, outdoor) and in different environmental conditions. These sensors have been combined into a compact unit and adapted for operation in site conditions by Beamagine. Once adapted, they have been installed in real site situations managed by COMSA, the UPC-CD6 has carried out the tasks of data capture, annotation and processing, and Sensofar Medical has contributed to the project with its experience in regulations and risk analysis. All this knowledge, currently non-existent, cannot be acquired in laboratory environments, as perception based on artificial intelligence needs to be trained in conditions of use, i.e. from data acquired on site, in real conditions.

Beyond the immediate market need, the project allows us to adapt and evaluate very new technology, and to discover its performance and limits in a market that is not very digitised. There is no doubt that this technology has great potential in terms of improved productivity, a significant reduction in face-to-face checks by technicians, the objectification of decisions taken, or the early detection of errors or deviations, among other long-term benefits. The project has shown the feasibility of applying combinations of sensors as a method of acquiring both scene and geometry information, allowing distance and position information to be extracted. It has also demonstrated the feasibility of applying artificial intelligence algorithms in construction environments and their viability as an element in the prevention of accidents in the workplace.