PLATFORFUTURE

Digital platform for food control and food safety 4.0

Nulab, in collaboration with COVAP (Cooperativa Ganadera del Valle de los Pedroches) and Cárnicas KIKO, is developing a digital platform that enables sensor connectivity, data storage and the development of mathematical models to assess risks in the food industry using Artificial Intelligence.

The platform, created within the framework of the PLATFORFUTURE project, has been coordinated by secpho, with the collaboration of NAGRIFOOD on behalf of the meat sector and has received funding from the European Union-Next Generation EU and the Ministry of Industry, Trade and Tourism in its programme of support for Innovative Business Groups 2021, as it is considered a technological innovation at national level.

The use of 4.0 technologies in production processes in the food sector allows for flexible and efficient production, better adaptation to the environment and more collaborative value chains.

The implementation of 4.0 technologies in the production processes of the food sector has grown slightly in recent years. The use of these technologies offers important benefits to the sector at a strategic and operational level, through more agile decision-making, flexible and efficient production, better adaptation to the environment and more collaborative value chains. Still, very few companies have embraced these technologies.

In the specific case of the agri-food industry, despite the high level of technification of the sector, the implementation of certain technologies such as artificial intelligence is not widespread. This is mainly due to the complexity of the products and manufacturing processes, as well as the variety and volume of data generated and the lack of knowledge about their use. In addition, a very special feature of the sector is that it works with “live” raw materials that undergo a great deal of variability depending on the time of harvest, weather conditions, etc., which makes the adjustment and optimisation of processes even more complex.

In addition, product quality and safety are a priority in the agri-food sector, which is obliged to comply with a large number of legal and commercial requirements. However, as far as quality control and food safety are concerned, although the controls that are carried out are strict, they have important shortcomings: many analyses are manual and therefore subjective, they are costly in terms of time and money, the information is not collected in real time, etc.

On the other hand, companies currently only sample a very low share of production, less than 1%, so it seems clear that control and safety in the agri-food industry needs to be strengthened.

PLATFORFUTURE proposes an effective solution based on Artificial Intelligence to assess risks in the food industry.

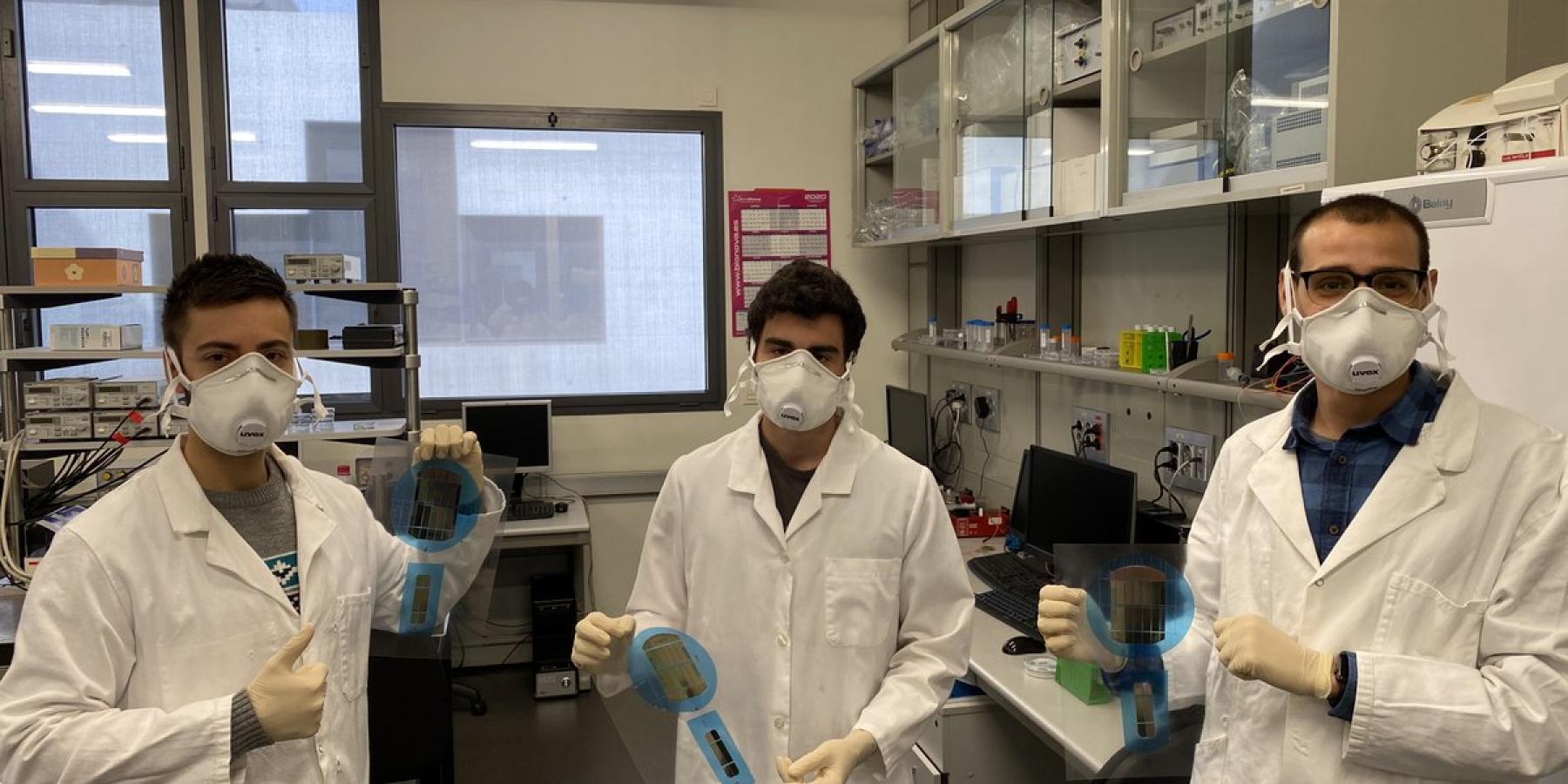

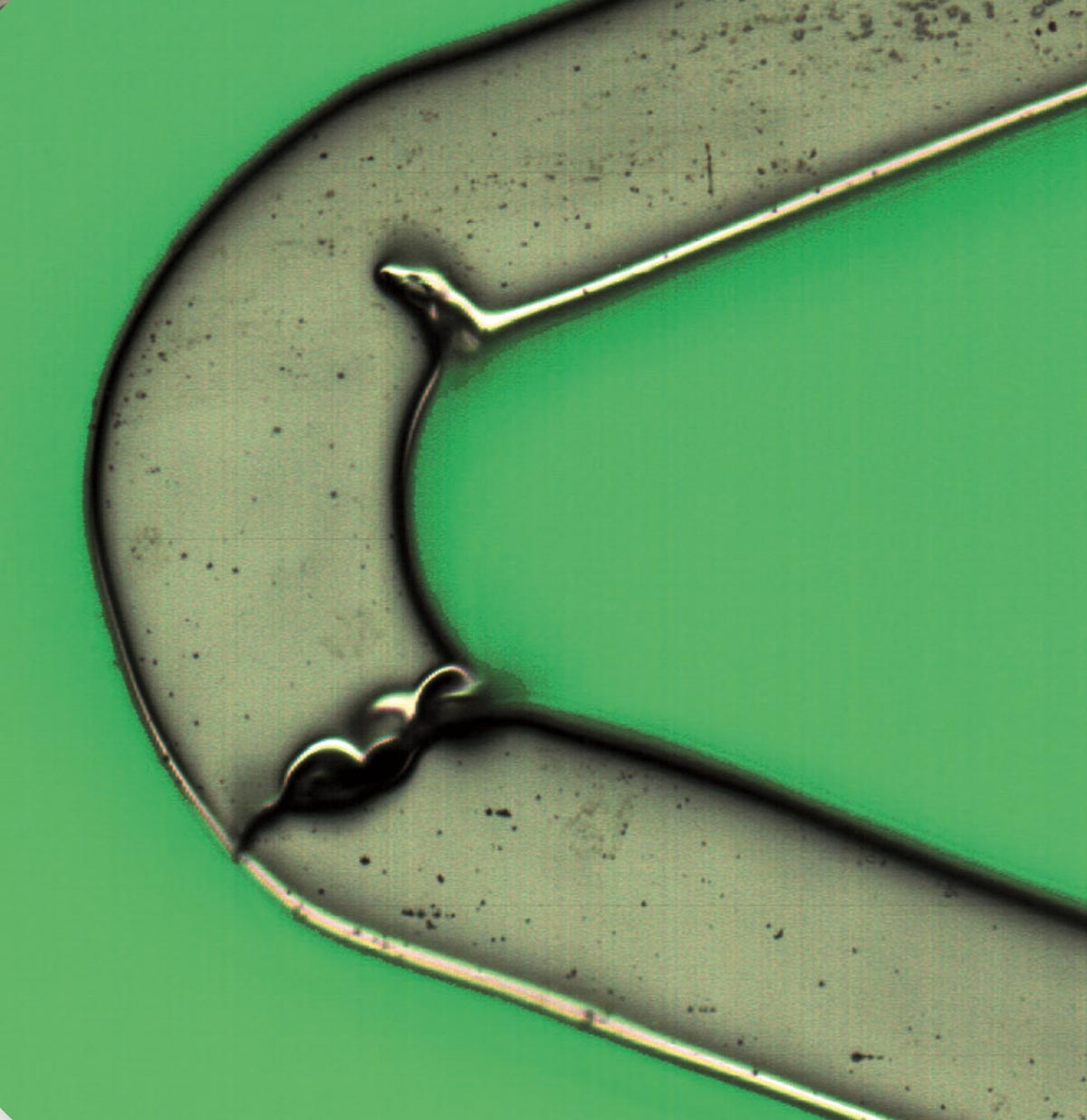

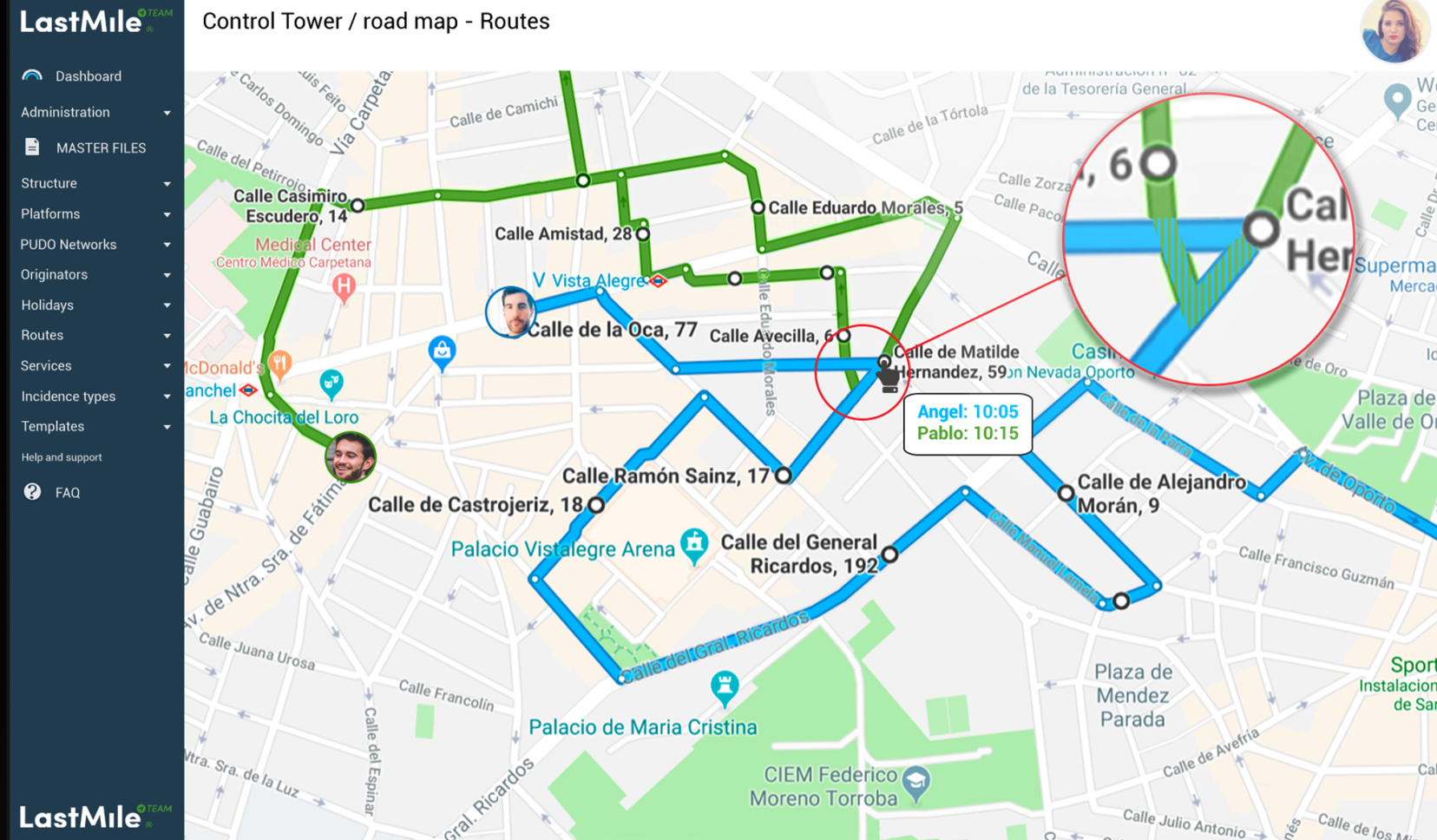

Data collection in COVAP of the “salchichón cular”, through Nulab’s mobile device.

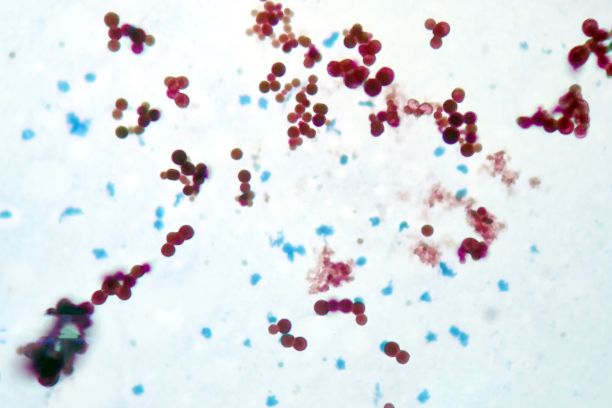

In this context, PLATFORFUTURE is presented as an innovative solution to ensure product control through the development of predictive models based on AI. Specifically, it aims to address the specific application identified in the agri-food sector of developing predictive models related to food safety control (Listeria monocytogenes events) in the food production process (maturation of cured sausages), based on the capture and acquisition of data through protocols and/or sensors.

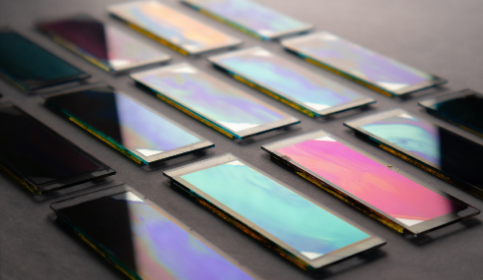

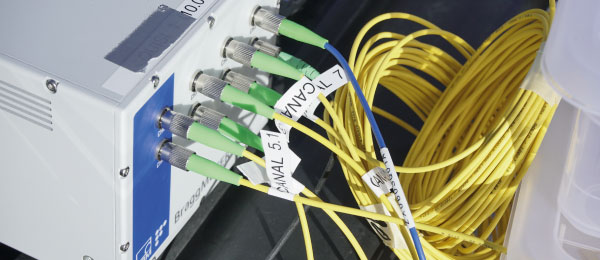

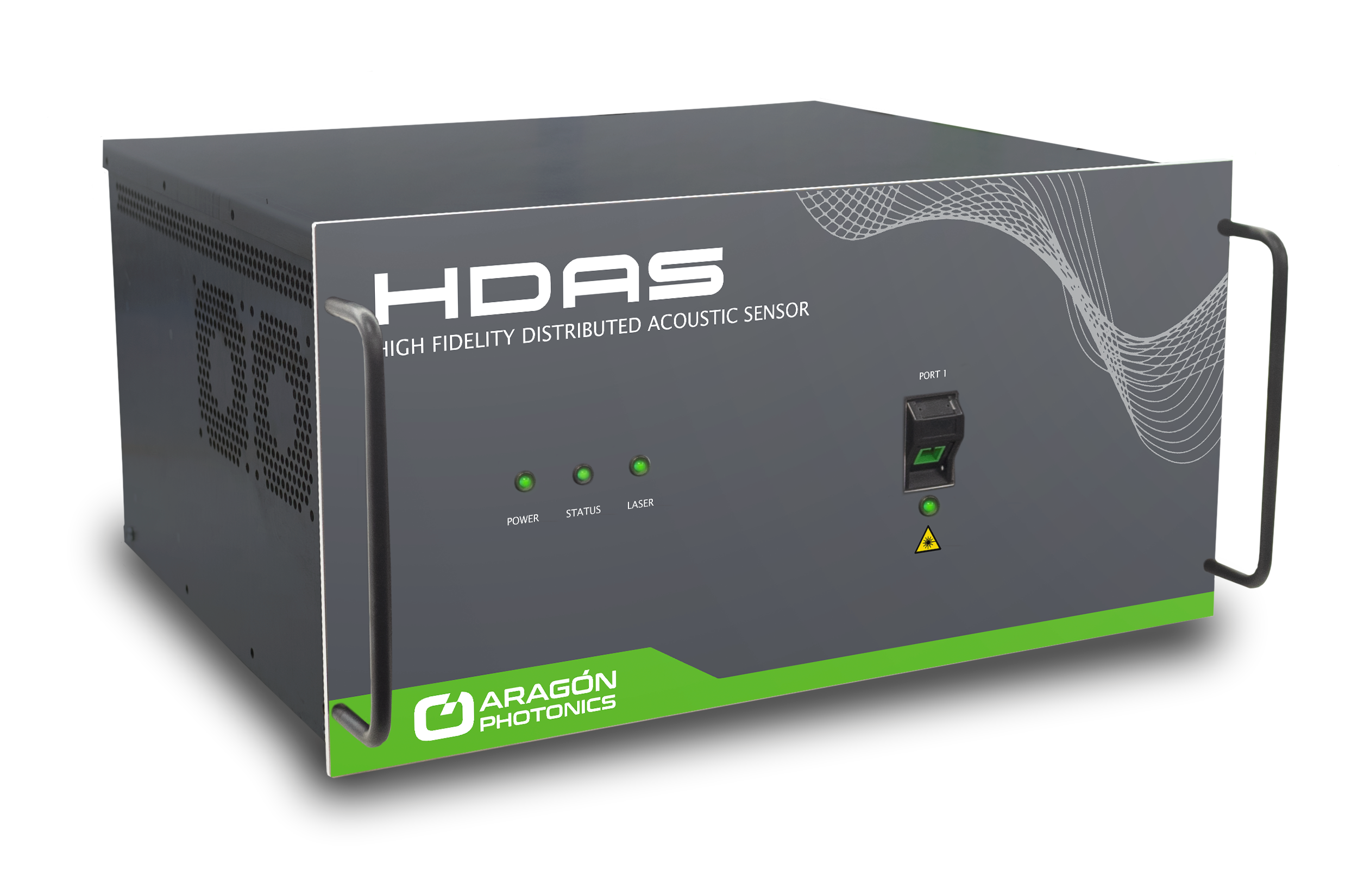

The main results obtained in the project are: on the one hand, a mobile APP has been developed for the connectivity of the Nulab portable NIR device to the digital platform (Cloud) and for analysis planning. In addition, a development has also been incorporated for the implementation of mathematical models and a web environment for user management.

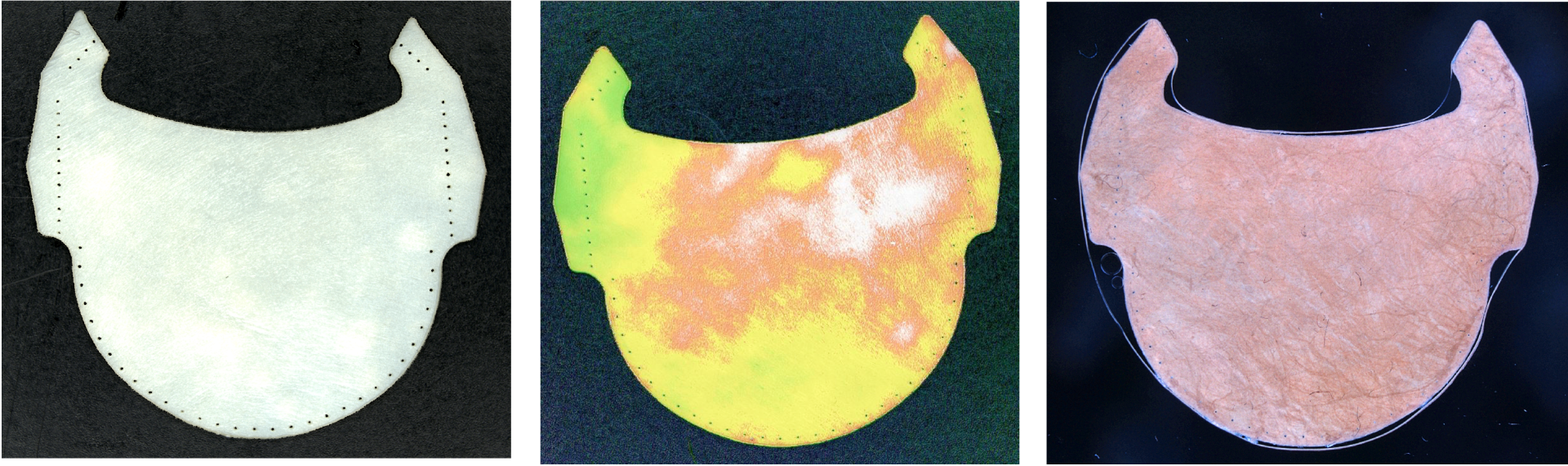

On the other hand, predictive models have been generated from the developed digital tool for two different applications. Firstly, the models are used to monitor water activity in salami and cured sausage products, and thus examine the microbiological risk of the drying process of cured products. The novelty introduced by these models is that it is possible to measure directly on the surface of the product, maintaining the accuracy levels of models on sliced products.

Secondly, the models allow to know the protein and fat composition of meat raw materials in order to inspect their quality.

Finally, the platform has been successfully validated by COVAP and Cárnicas KIKO, partner meat companies of the developed models.