New local production system using additive manufacturing to automate industrial laser cutting processes

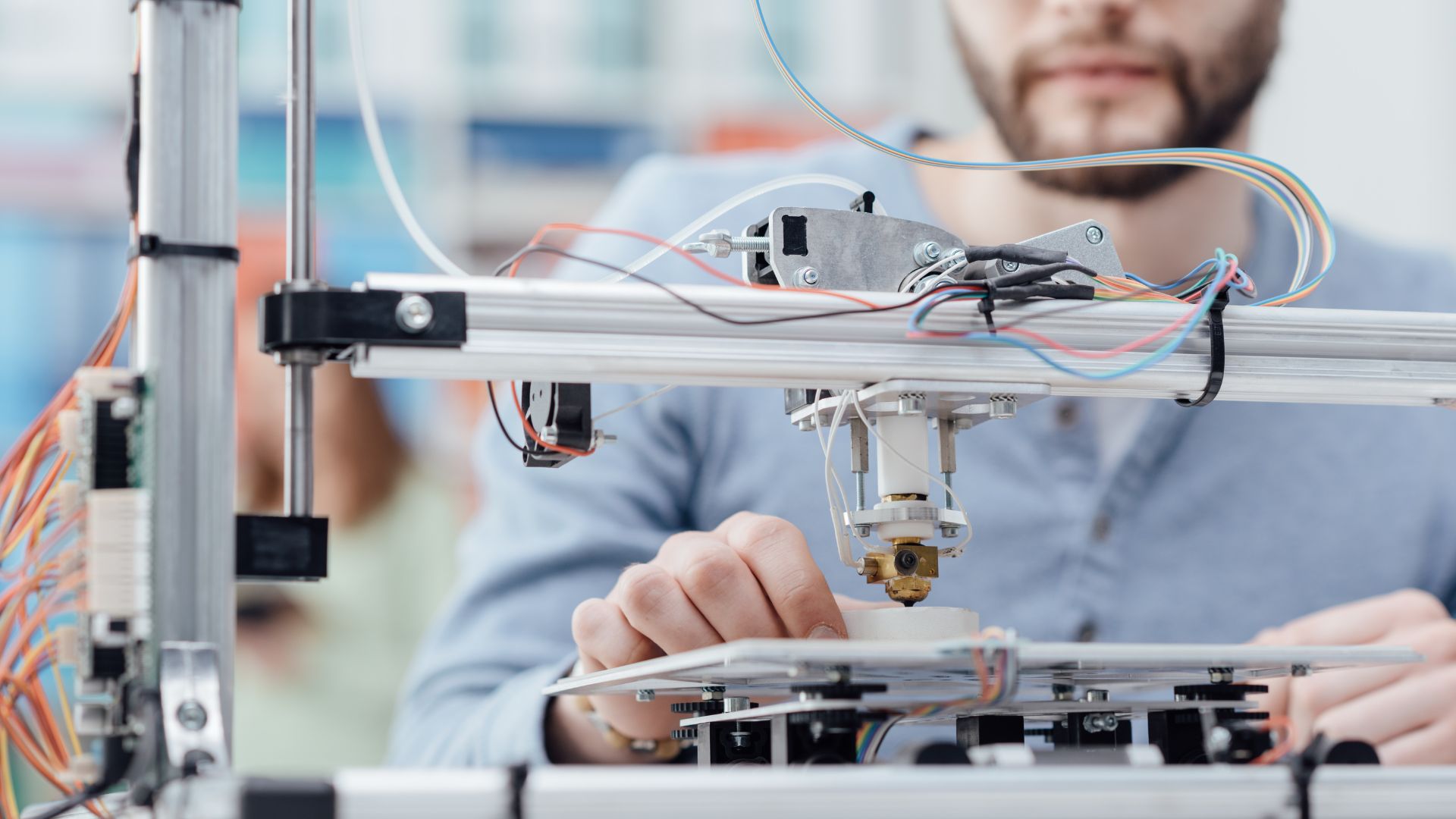

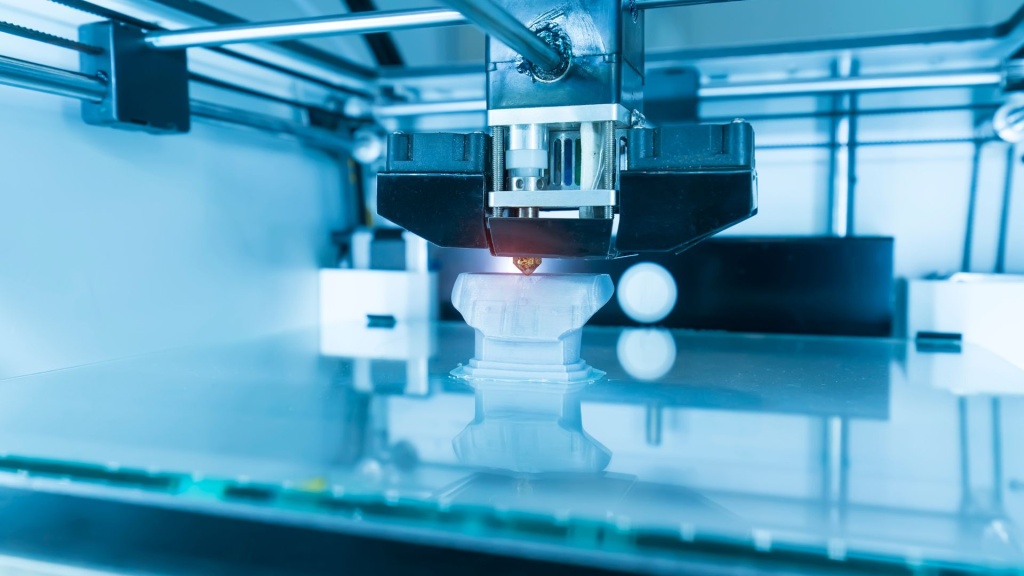

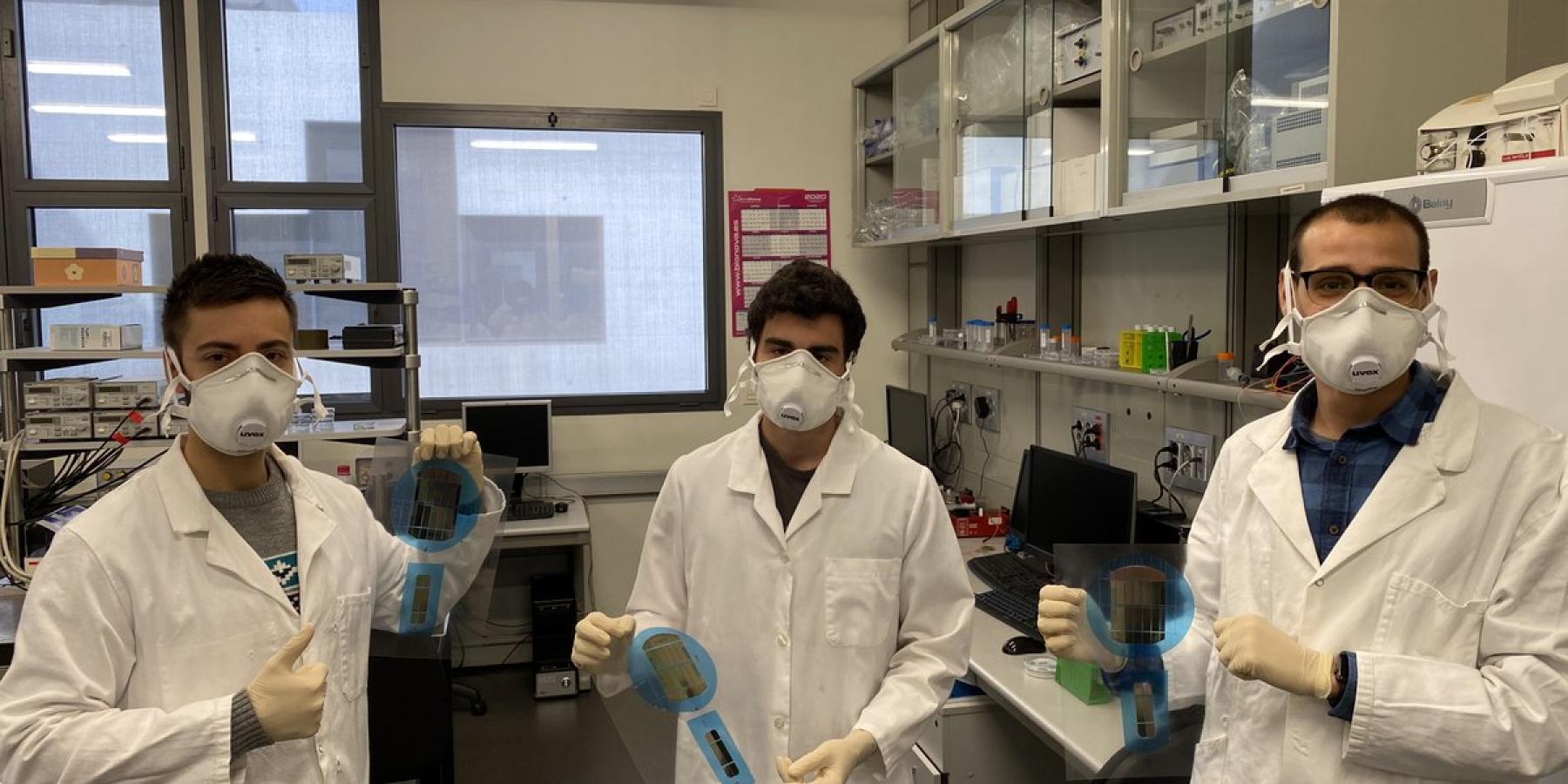

Four Spanish entities –SnellOptics, Mapsi Photonics, CD6-UPC y Monocrom– with the coordination of secpho, collaborate in the OTPILASER project to create a new production system that will optimize the manufacture of industrial cutting and welding lasers. The new system will locally manufacture the parts needed to couple the optics of these lasers, eliminating the dependence on third countries that the Spanish market currently has for this type of service. In addition, the new method, based on additive manufacturing, will make it possible to obtain parts up to 90% faster, at a lower cost and without generating waste.

On the other hand, OPTILASER’s results will also be applied to the development of infrared thermal emitters (MIR), widely used for selective gas detection, in order to optimize their design and reduce their production costs.

The initiative has received funding from the Ministry of Industry, Trade and Tourism corresponding to Next Generation EU funds, canalised through the support programme for Innovative Business Groups, whose objective is to digitalise industry.

Este proyecto garantiza que Europa aumente su capacidad de autoabastecimiento reduciendo su dependencia de China, único proveedor de los procesos productivos de corte láser

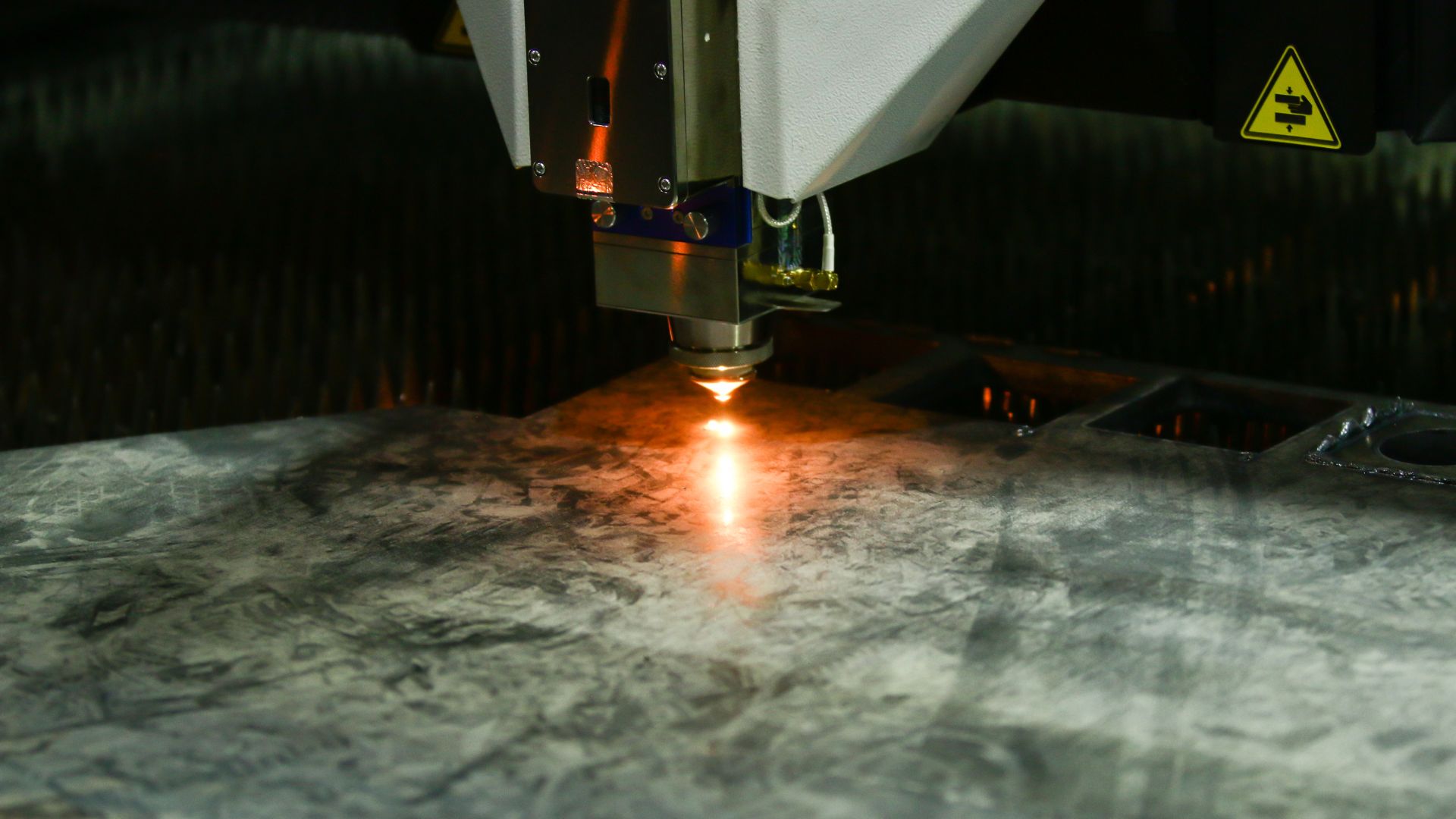

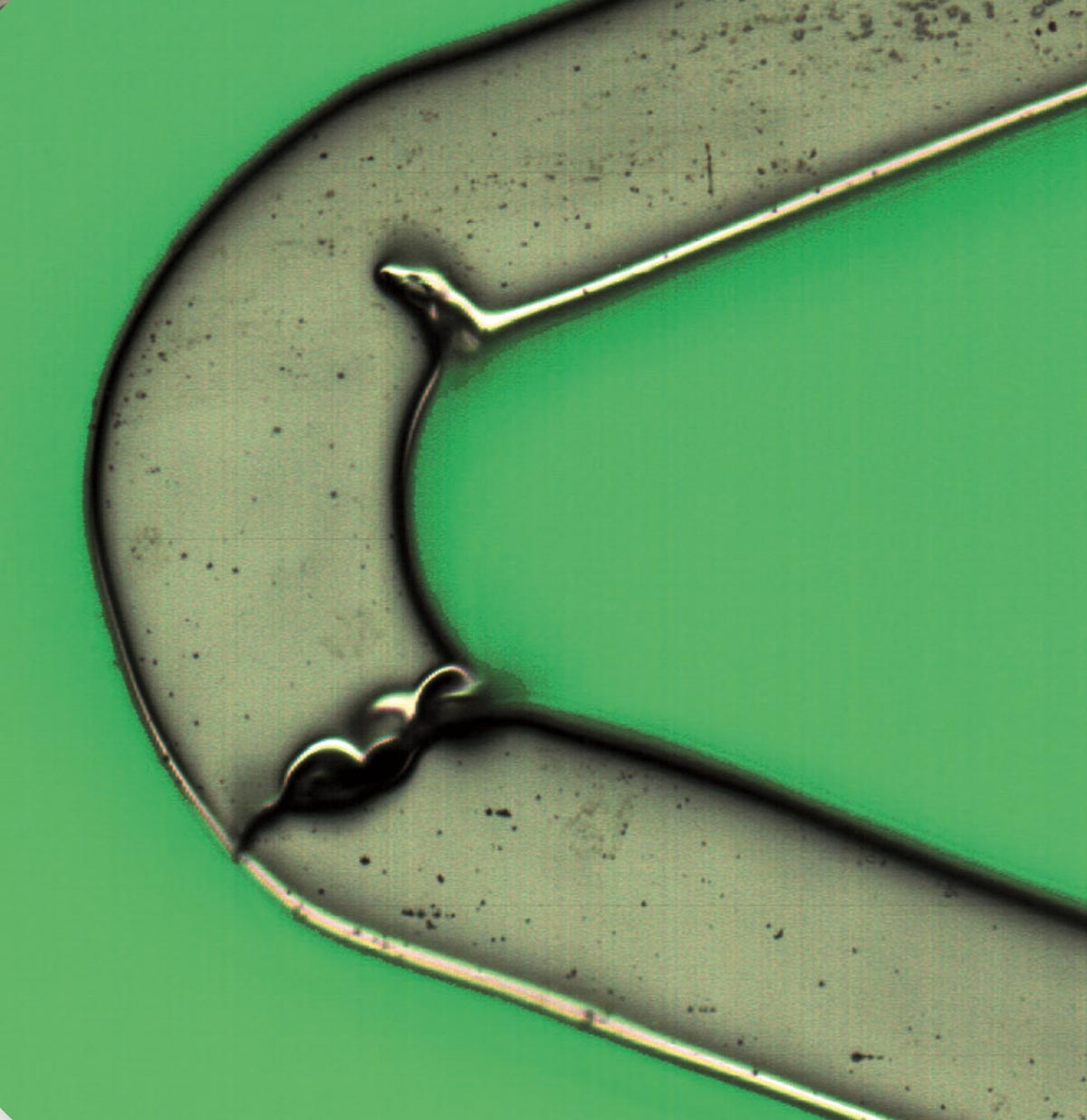

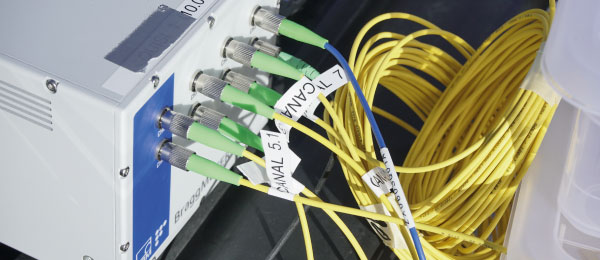

Laser cutting is a widely used technique in the industry that offers high cutting speeds with excellent quality. In addition, it is a clean technology that does not pollute or use chemicals. However, its production process has a high cost due to the amount of time needed to align all the optical elements involved as well as the cost of these, especially in the micro optics part, which is controlled by only three manufacturers worldwide.

Thus, the current situation of laser cutting production processes in Spain depends mainly on the service of a very limited number of suppliers located in China, with service times of 6 months and which are strongly affected by the supply crisis we are experiencing today. This commercial dependence forces companies to give long delivery times or to dedicate economic resources to build a sufficient safety stock, so the Spanish market is strongly limited.

Furthermore, the new waves of COVID-19 suffered by Asian countries in the first months of 2022 and the resulting logistical problems, reaffirm the importance for Europe to increase its self-supply capacity, reducing its dependence on third countries. In this context, the Spanish government, through the OPTILASER project, is committed to strengthening the design and production capacity of the industry in Spain from an integral perspective.

Compared to traditional manufacturing techniques, additive manufacturing allows parts to be produced up to 90% faster, at a lower cost, without waste and more sustainable.

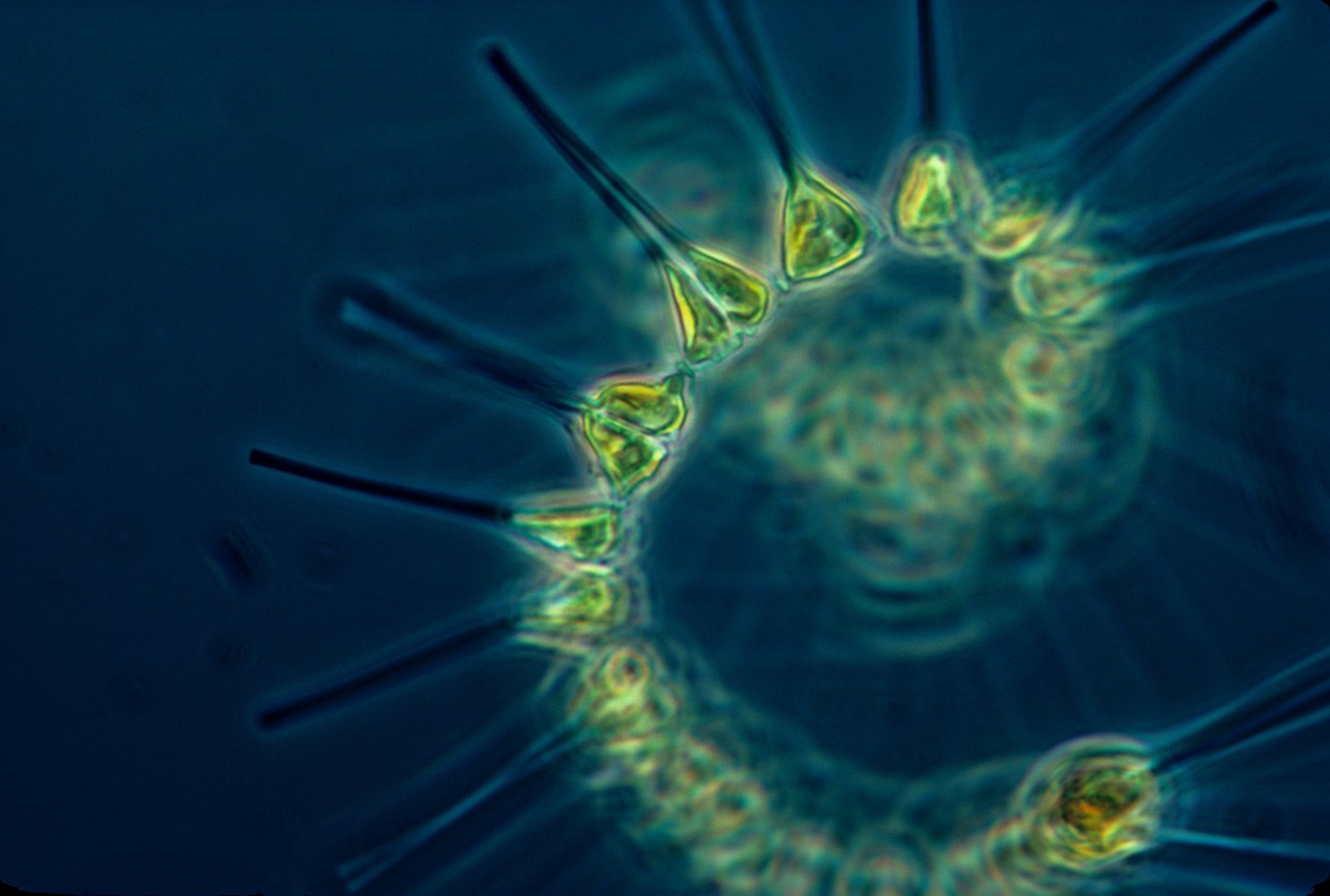

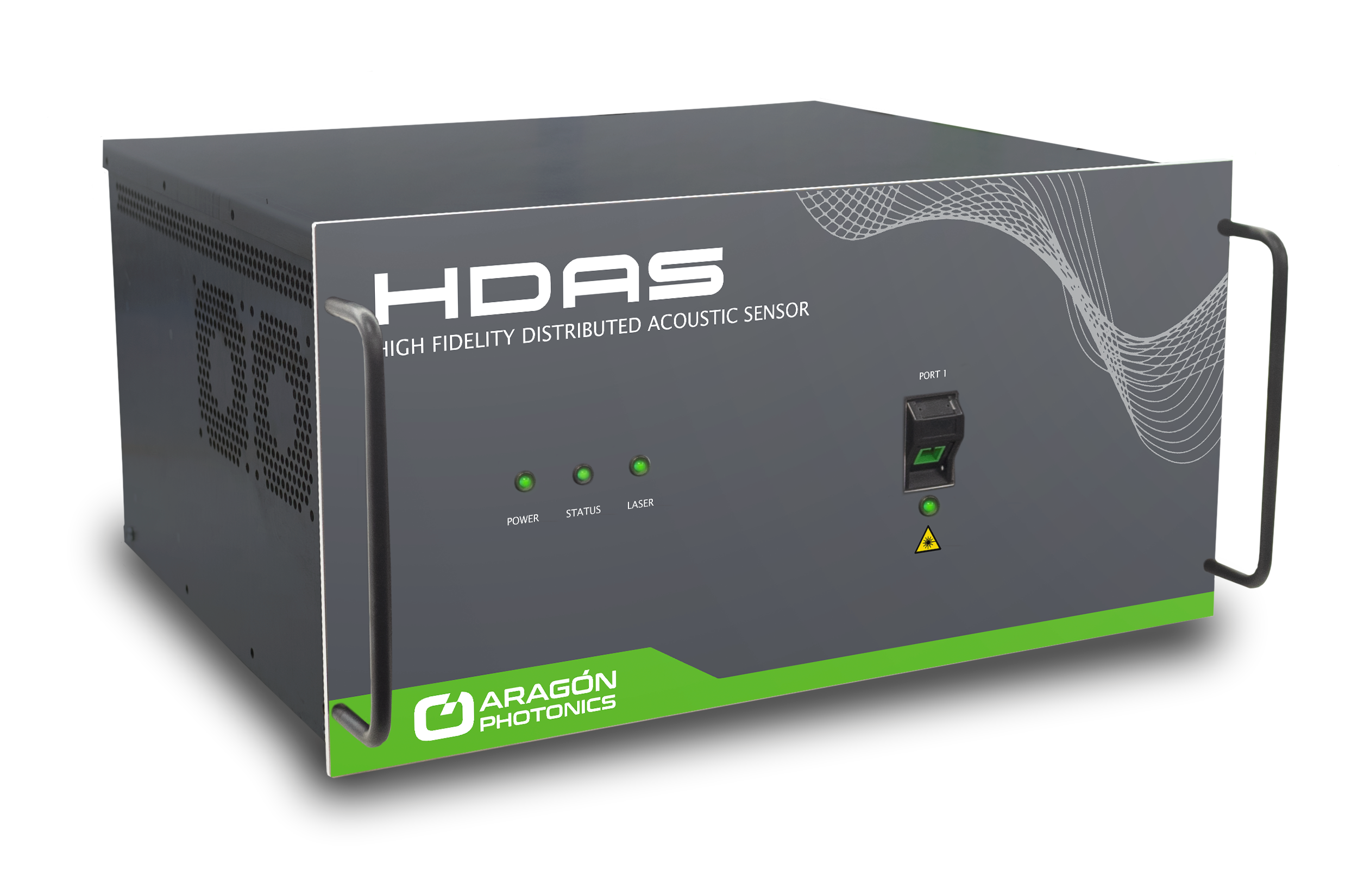

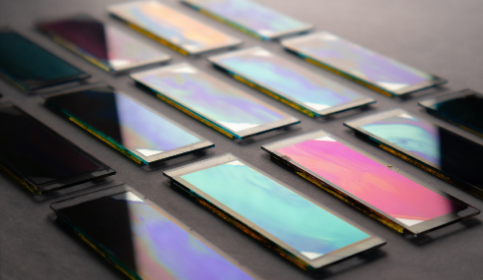

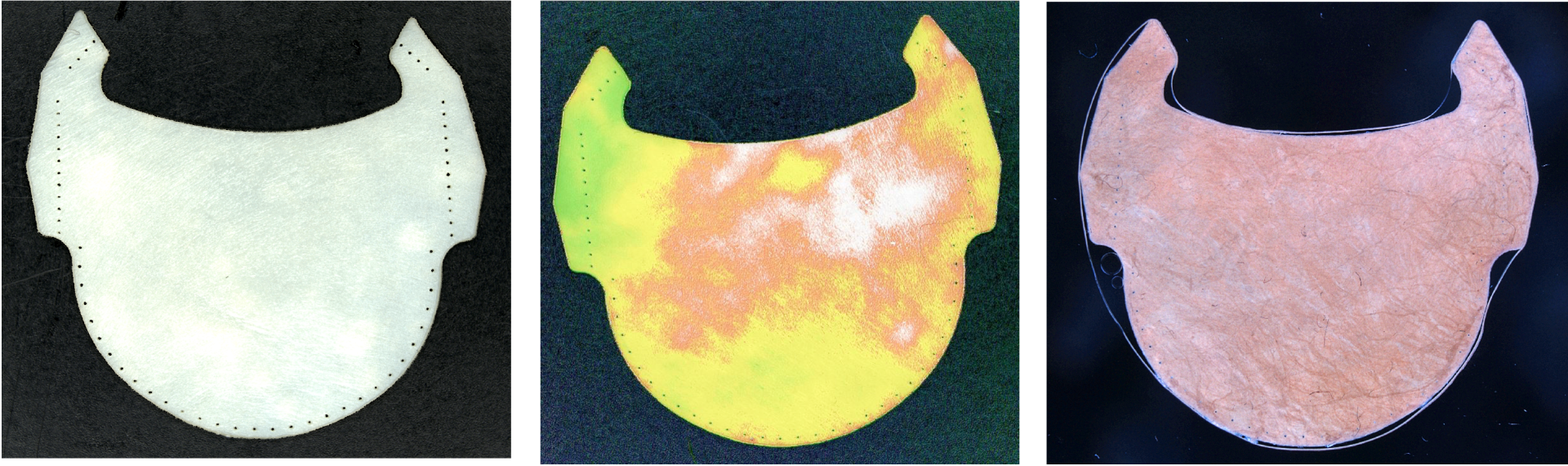

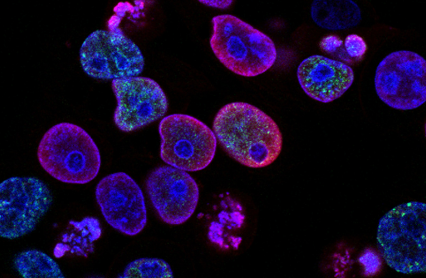

The OPTILASER results will also allow optimizing the development process of thermal infrared emitters (MIR) used for selective gas detection. Currently, selective emission in the MIR has major limitations in terms of production cost and selectivity without the use of filters. However, macroporous silicon, a metamaterial that exhibits the property of selective emission when heated, could overcome these problems as it allows high emissivity at low emissivity.

In this context, OPTILASER intends to design and produce, on the one hand, a new coupling system that manages to adhere the silicon to the heating resistor – the main challenge of this type of emitter – and, on the other hand, an optical system that makes the most of the power emitted by the emitter. With this optical coupling system in place, it will be possible to commercialize macroporous silicon thermal emitters with high emissivity, something that was not very feasible to date.