Augmented reality and collaborative robots for remote industrial equipment installation

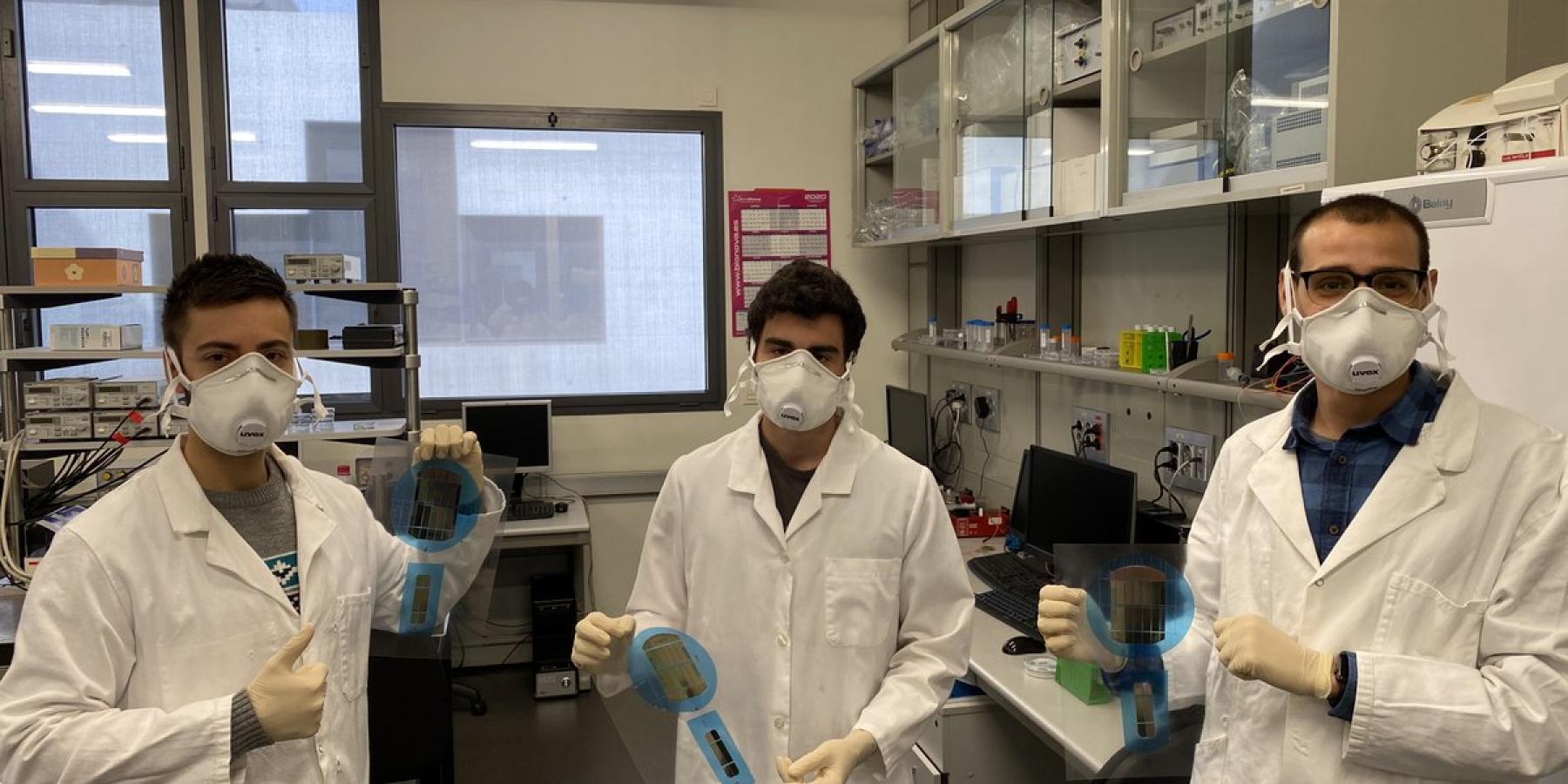

The technology suppliers Visiona, Robotnik, Fivecomm and the transport operator Metro Ligero Oeste as user, with the coordination of secpho, collaborate in the HERMES project to develop and validate a system that allows expert personnel to remotely monitor and validate the result of different tasks performed by an operator during the installation of a piece of equipment.

The initiative has received funding from the Ministry of Industry, Trade and Tourism corresponding to Next Generation EU funds, canalised through the support programme for Innovative Business Groups, whose objective is to digitalise industry.

Currently, digital transformation leads us to implement remote solutions to improve all types of workflows, prioritizing simplicity and speed of action

Technology has radically altered the way we think about work. Although many employees still commute from home to the workplace, companies are becoming increasingly remote. A study conducted by IBM’s Institute for Business Value (IBV) indicates how the new consumer habits of Spaniards as a result of the COVID 19 pandemic are here to stay, with 70% of respondents preferring to continue telecommuting once the pandemic is under control, and 51% indicating that they prefer to continue using telemedicine to access a medical professional.

So, if before preference was given to face-to-face (in activities such as shopping, studies and training or even going to the doctor), now, virtual alternatives are being sought, opting for the digitization of some of these old habits. These new behaviors bring immediate consequences on different sectors of activity such as retail, healthcare, transportation, and expectations of combined physical and digital experiences.

From a business point of view, digitalization impacts not only the employee-company relationship but also the customer-company relationship.

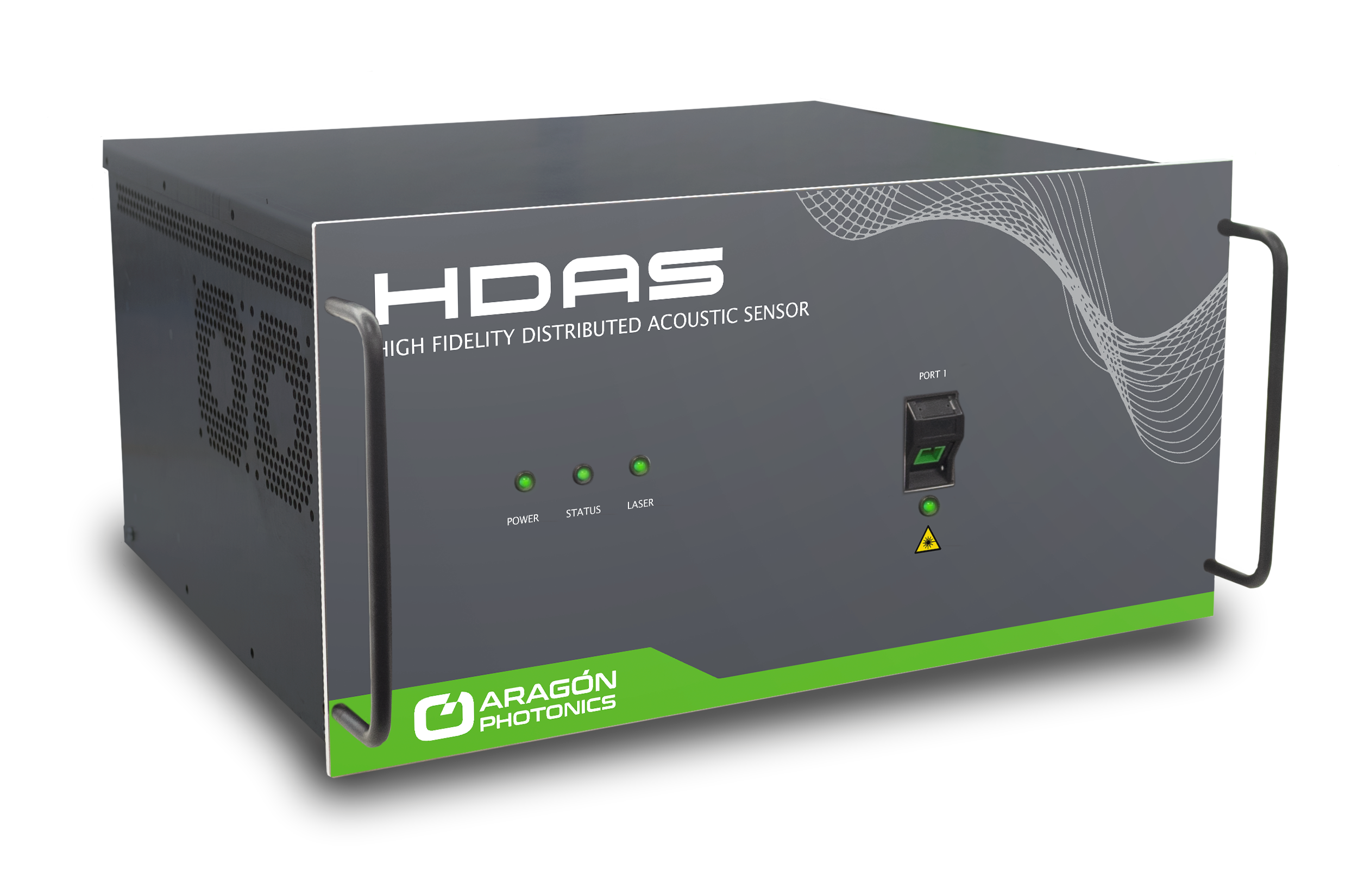

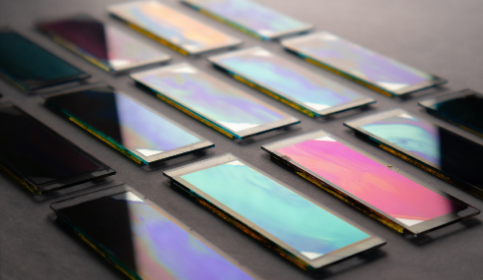

Technology companies involved in the design and manufacture of equipment for Industry 4.0 need to make the final adjustments on site

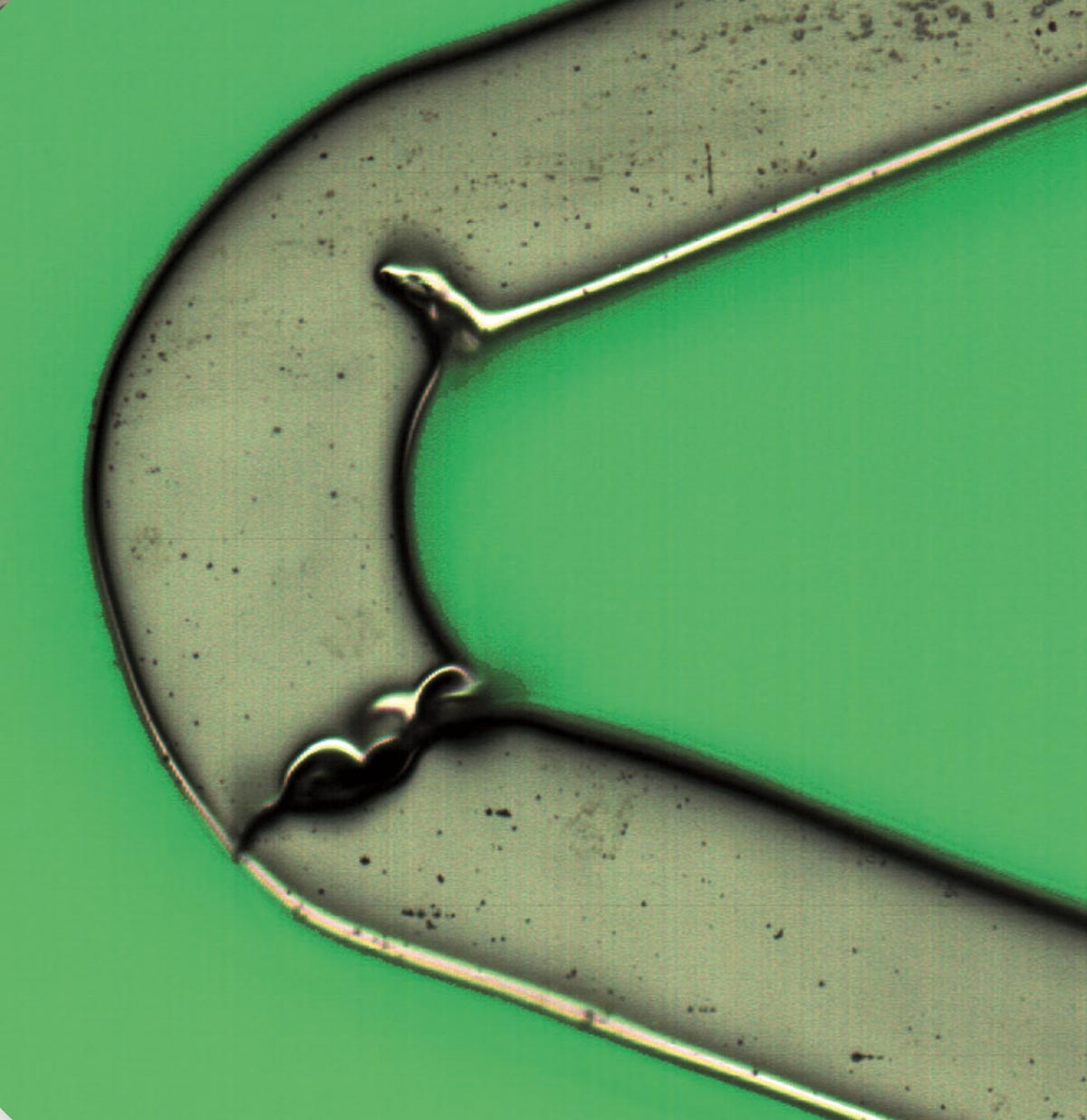

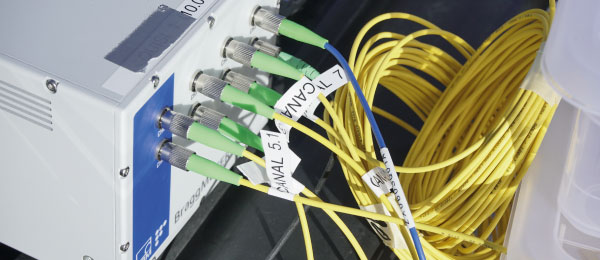

In this sense, the market is demanding a change in the customer support model, which is more effective and sustainable. Many technology companies involved in the design and manufacture of equipment for Industry 4.0 -such as machine vision equipment, special test machines, quality control systems, etc.- need to make the final adjustments to the machine, possible calibrations, verifications, etc., on site at the place where the equipment is installed. To close these turnkey projects, at present, it is necessary the action of the experts who have designed and programmed the machine, once it has been installed, with the consequent investment in time and resources (travel costs, hours of technical personnel, opportunity cost for not having that technician available for other projects, etc.).

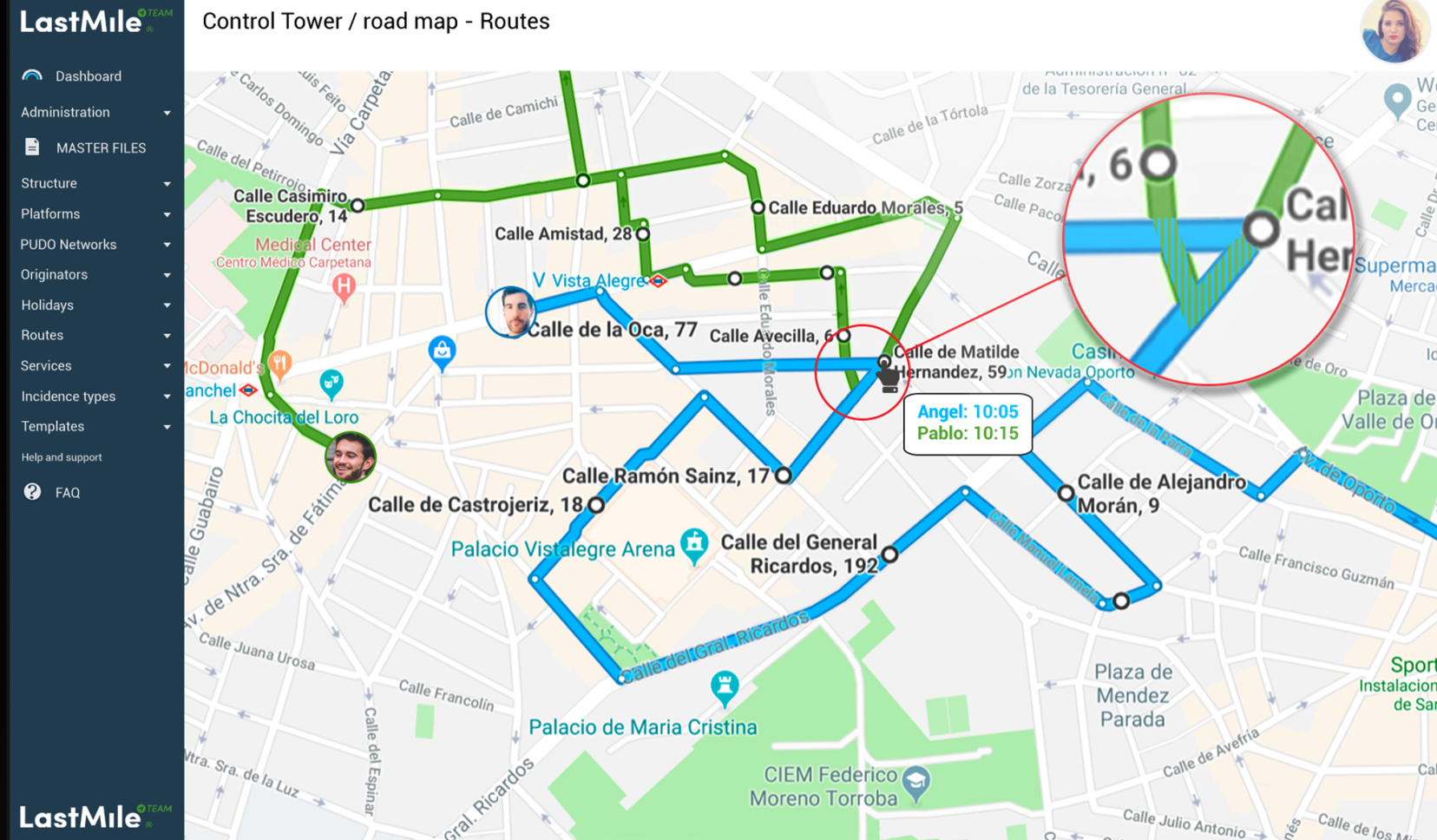

HERMES is the project that proposes to implement a solution to this situation based on augmented reality and collaborative robots. Thanks to the application of these innovative technologies in the process, experts will be able to interact with local operators remotely to make the final adjustments and complete the installation of a piece of equipment, as well as its subsequent maintenance.