Thermography with intelligent detection to protect the metal-mechanical sector from laser radiation emissions.

SMEs in the metalworking industry need cost-effective and reliable solutions that enable them to use laser technology safely, efficiently and in accordance with the new standards demanded by the global market.

In this context, ProCareLight, EXOM Engineering, Danobat Group and New Infrered Technologies have collaborated in the CLAUDIT Project to develop a thermographic laser radiation protection system with an intelligent detection threshold to increase productivity and safety in the metalworking industry.

The project, led by secpho, has had the collaboration of the Spanish Association of Machine Tool Manufacturers (AFM) and funding from the Ministry of Industry, Trade and Tourism and the European Union-Next Generation EU, within the programme to support Innovative Business Groups, which aims to digitise industry.

The current protection systems for laser installation booths have high implementation and maintenance costs.

The evolution of European industry towards the Industry 4.0 concept will allow it to maintain and improve its competitiveness by reaching the new standards demanded globally. We are already seeing this transformation in sectors such as the automotive and aeronautics industries, and in the near future we will see companies of all sizes and sectors adopting the new methods and technologies of industrial digitisation.

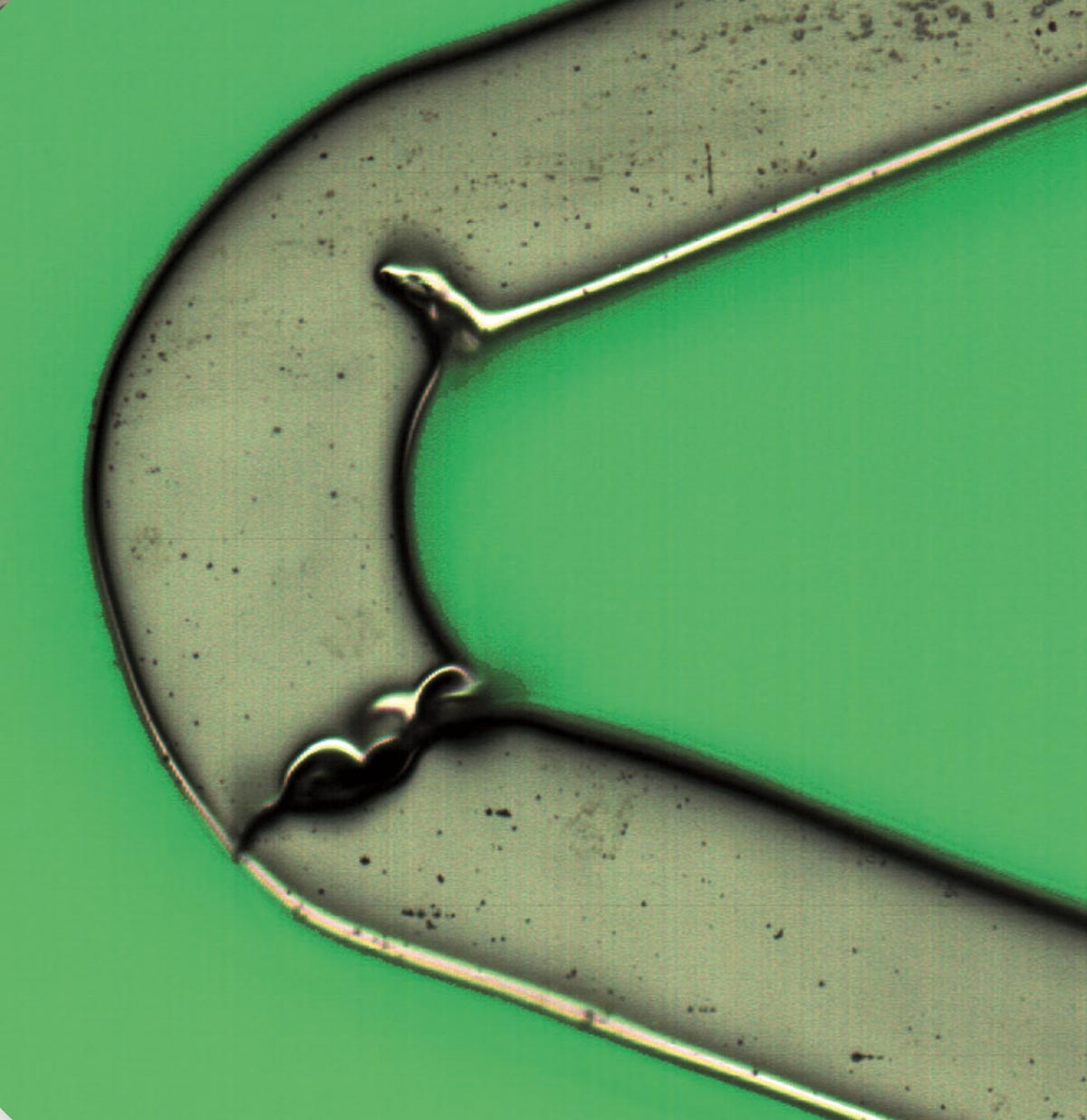

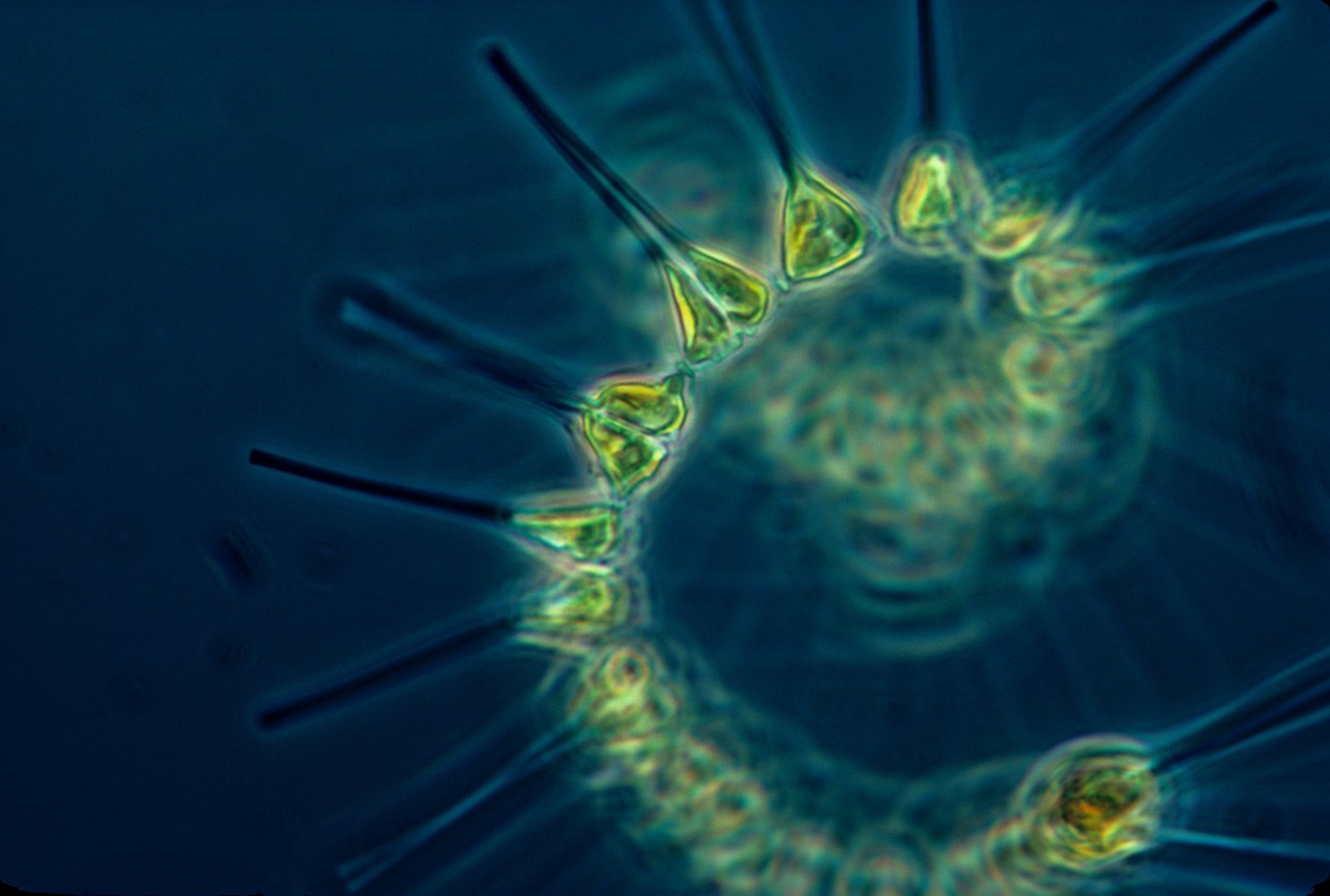

An essential technology for Industry 4.0 is the laser, which allows cutting, welding, marking, texturing, and even manufacturing parts by deposition of material particles, more widely known as additive manufacturing. However, this fundamental element of modern industry carries some health risks in the event of accidental exposure to the laser beam.

There are a number of active protection systems on the market for laser installation cabinets, which involve high implementation and, in some cases, maintenance costs. All of them require some kind of intervention after each detection, which includes the costs of the intervention itself and the necessary machine downtime for the duration of the intervention.

There are a number of active protection systems on the market for laser installation cabinets, which involve high implementation and, in some cases, maintenance costs. All of them require some kind of intervention after each detection, which includes the costs of the intervention itself and the necessary machine downtime for the duration of the intervention.

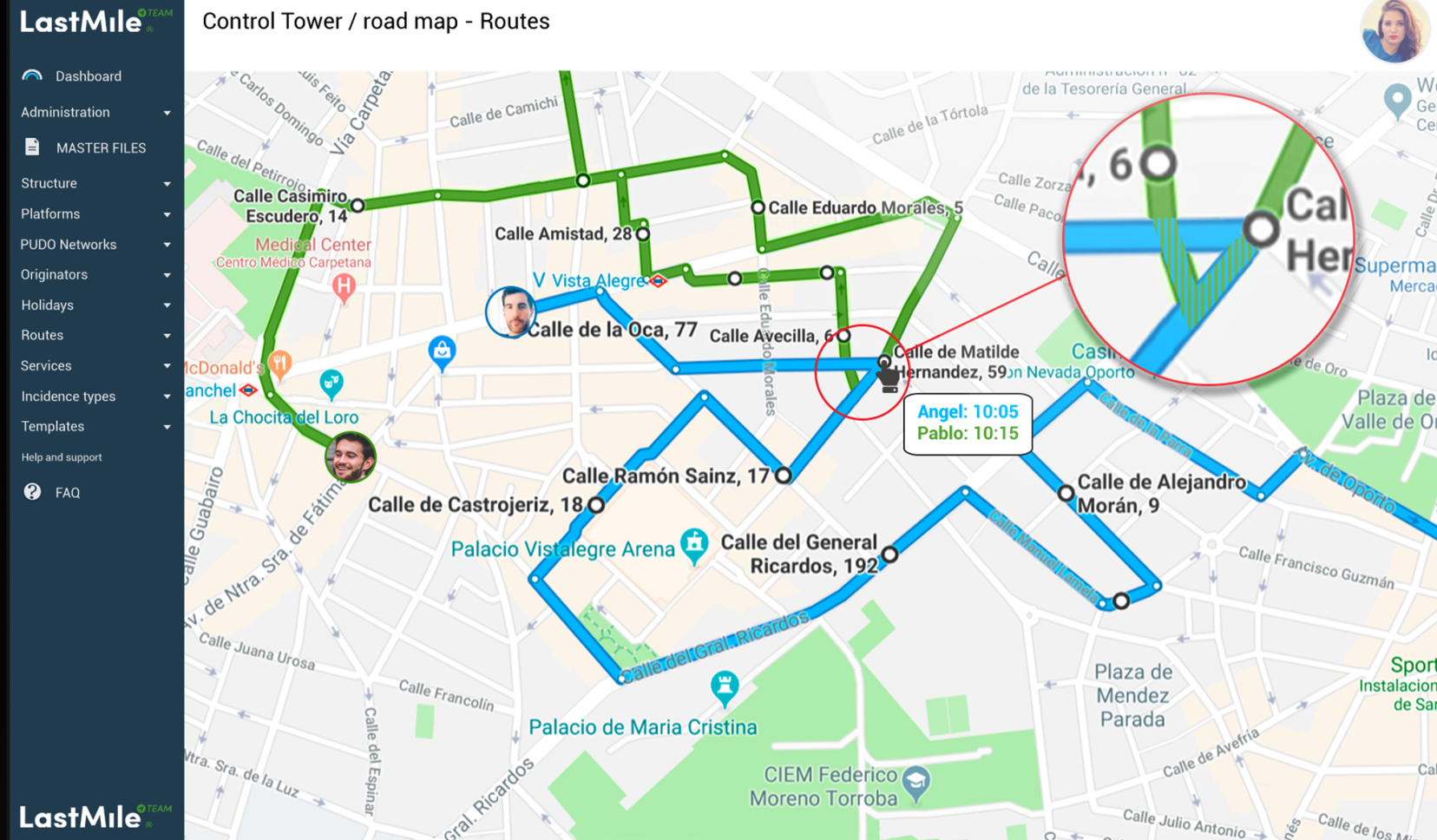

Although these solutions are already applied by many large companies, their costs are excessively high for SMEs and can therefore delay their adaptation to the needs of modernisation and digitisation of their production processes and, therefore, reduce their competitiveness. In addition, the metal-mechanical industry very often works for customers who are waiting for their parts with just-in-time logistics systems, so it has to face penalties in case an unforeseen failure forces it to stop its machines. There is therefore a need for a solution beyond the currently available products to set up active cabinets for laser systems at a lower cost and, above all, whose operating costs and machine downtimes are drastically reduced. It is therefore clear that the metal-mechanical industry (and others) needs economical and reliable solutions that enable it to use laser technology safely, efficiently and in accordance with the new standards demanded by the global market, and even more so if they are SMEs whose modest resources will not allow them to afford large investments and of course penalties for failure to meet the delivery deadlines demanded by their customers.

CLAUDIT economically and efficiently detects any damage to the enclosure to increase the productivity and safety of the system.

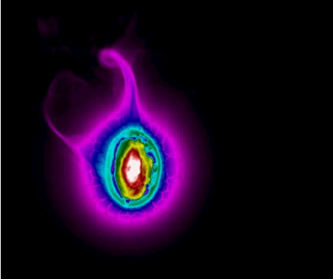

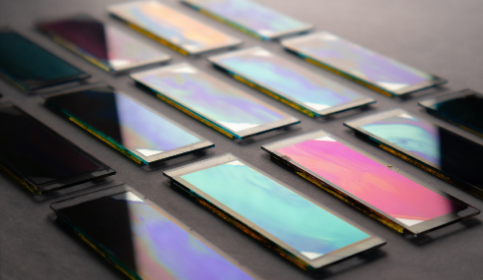

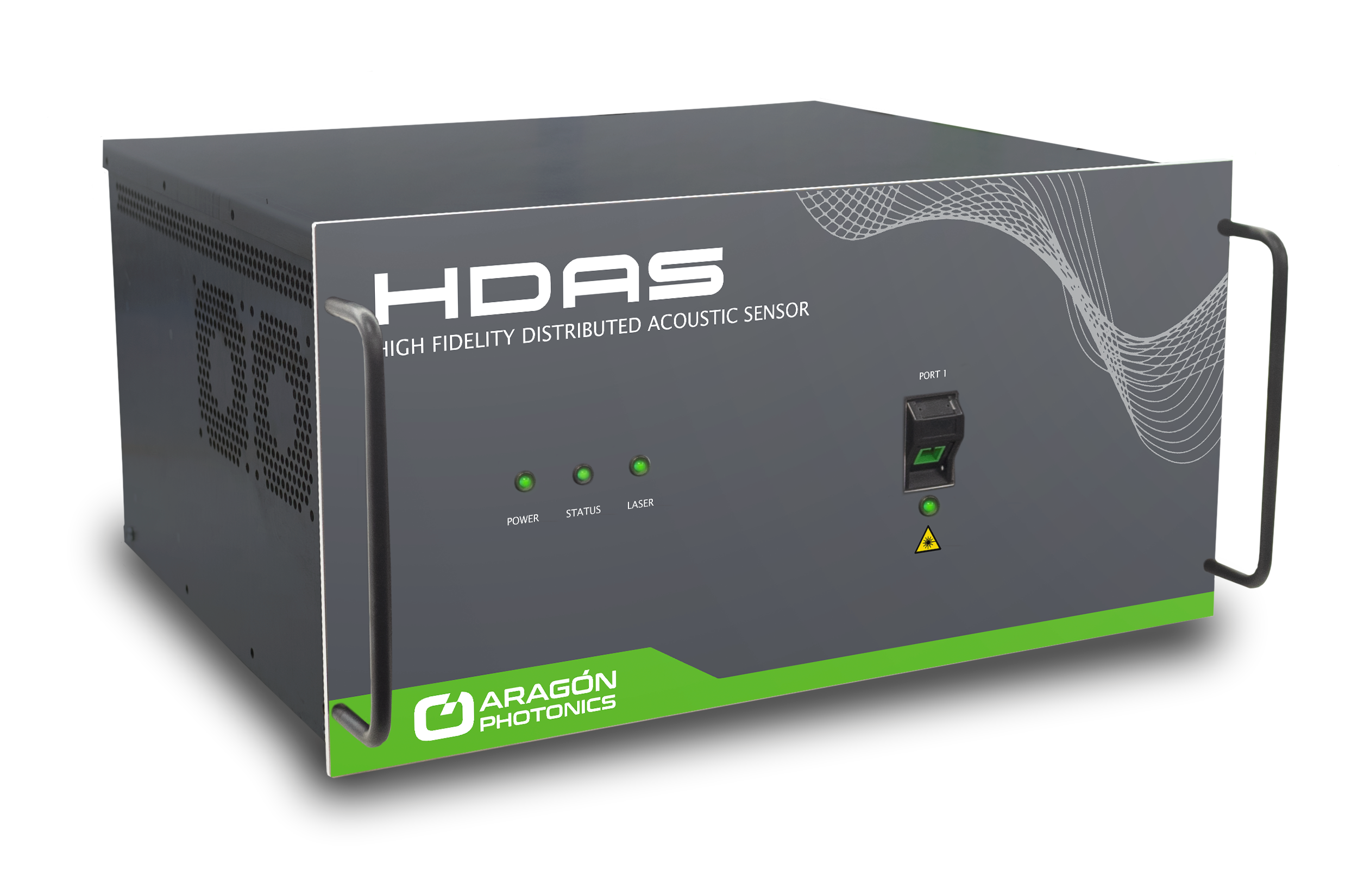

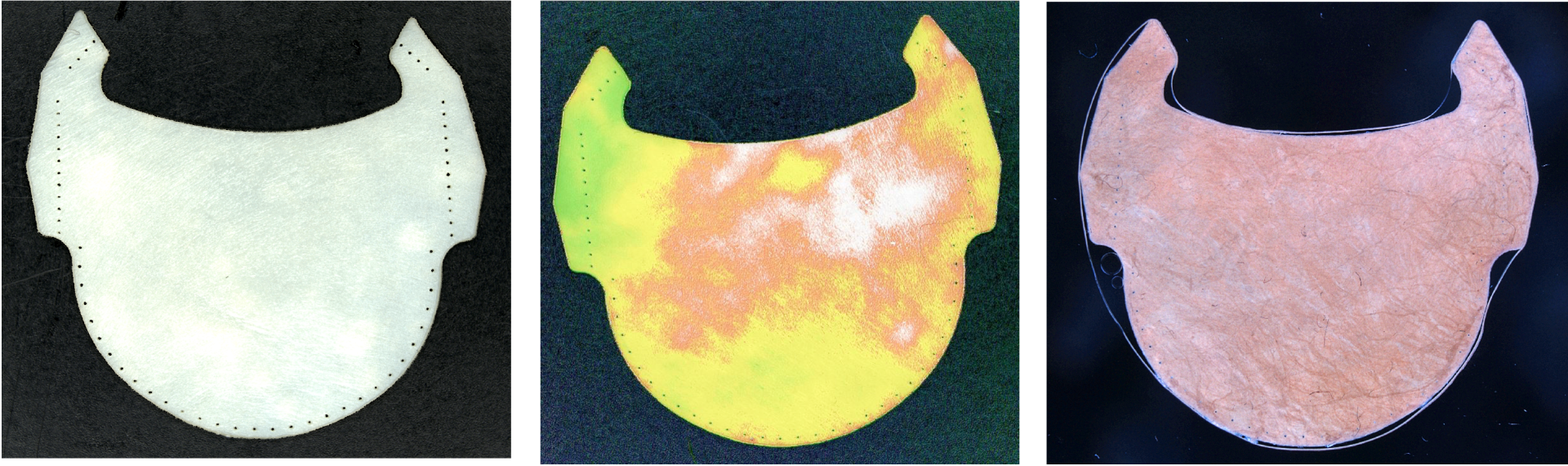

CLAUDIT is the project that has sought a solution to this situation, developing sensors based on the fusion of cameras in the near and far infrared range, which can remotely detect whether parts of the enclosure are subject to sudden and intense irradiation and heating.

CLAUDIT’s revolutionary idea is to detect any faults at thresholds lower than the damage to the inside face of the enclosure, thus avoiding costly repairs and lengthy machine downtimes. This improves productivity and facilitates the adoption of laser technology to achieve Industry 4.0 standards by small and medium-sized companies in the industry. Moreover, this functionality is implemented in a compact and easy-to-install device.

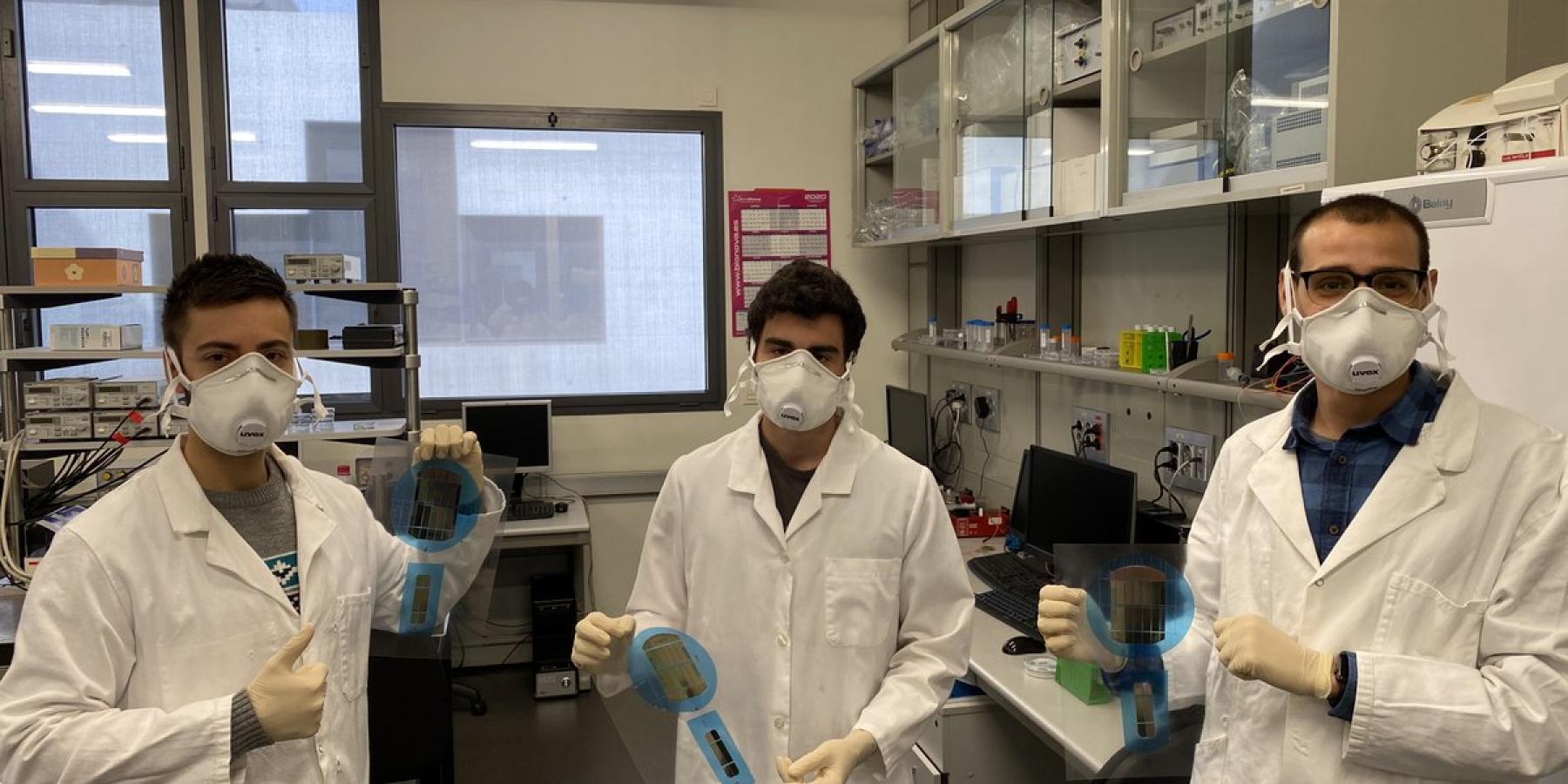

Within the framework of the project, a testing and optimisation phase has been included, implementing a pilot installation in a real environment in which the behaviour of the equipment has been verified by analysing use cases with the aim of guaranteeing 100% reliability and avoiding false alarms.